Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | Power (KW) | Chamber Type | Maximum Feeding Size (mm) |

| MG700 | 500 - 560 | ECX | 350 |

| EC | 300 | ||

| C | 240 | ||

| MC | 195 | ||

| M | 155 | ||

| F | 90 |

| Model | Tight Side Discharge Port (mm) Corresponding Production Capacity (t/h) | |||||||||||

| 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | 57 | 64 | 70 | |

| ECX | 430 - 559 | 453 - 807 | 517 - 920 | 571 - 1017 | 625 - 1113 | 688 - 1226 | 743 - 1323 | 807 - 1436 | 861 - 1264 | |||

| EC | 448 - 588 | 477 - 849 | 544 - 968 | 601 - 1070 | 658 - 1172 | 725 - 1291 | 782 - 1393 | 849 - 1512 | 906 - 1331 | |||

| C | 406 | 433 - 636 | 461 - 893 | 525 - 1018 | 581 - 1125 | 636 - 1232 | 700 - 1357 | 756 - 1464 | 820 - 1461 | 876 - 1286 | ||

| MC | 380 - 440 | 406 - 722 | 432 - 837 | 492 - 954 | 544 - 1055 | 596 - 1155 | 657 - 1272 | 708 - 1373 | 769 - 1370 | 821 - 1206 | ||

| M | 400 - 563 | 428 - 786 | 455 - 836 | 519 - 953 | 573 - 1054 | 628 - 1154 | 692 - 1271 | 746 - 1372 | 810 - 1248 | 865 - 1098 | ||

| F | 360 - 395 | 385 - 655 | 414 - 704 | 442 - 752 | 470 - 800 | 535 - 912 | 592 - 857 | 649 - 718 | ||||

*Note: The processing capacity of the E-SMG700 cone crusher may vary with different materials and feeding sizes.

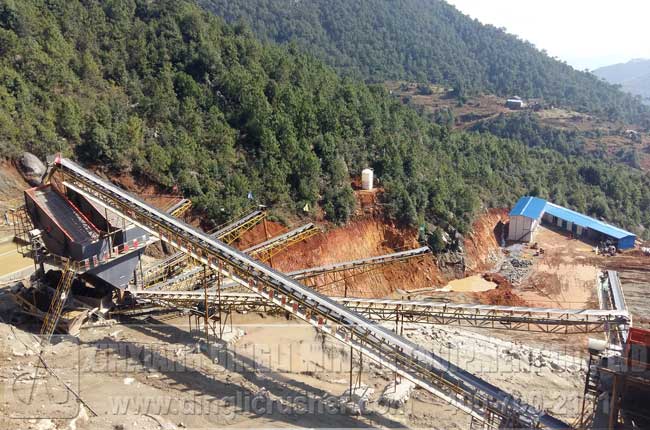

The above pictures show production site of hard rock crusher plant. Unlike traditional crushing plant it adopts only one set of hard rock crusher to complete the crushing process which greatly reduces the equipment investment and increase

This 500tph stone production line configured by Xinxiang Dingli in Pingliang Gansu mainly adopts PCZ1615 heavy hammer crusher with hourly capacity of 4200-500 ton ZG2038 vibrating feeder and several sets of our efficient vibrating screen.

On the production site we equipped our equipment on the cement ba

We can carefully select the crushing chamber and alloy materials suitable for specific crushing applications for the E-SMG series cone crushers. By deeply analyzing different crushing tasks, such as the hardness, particle size of the material and the expected output, the most suitable combination of chamber type and alloy material is determined. The appropriate chamber design can skillfully guide the flow and crushing of the material in the crushing chamber, reduce energy waste and significantly improve the performance of the crusher. For example, when processing high-hardness ores, the selection of a specific chamber type and wear-resistant alloy material can make the crushing process more smooth and efficient and improve the overall production efficiency.

The proper chamber design not only helps to improve the crusher performance but also plays a crucial role in prolonging the liner life. During the crushing process, the reasonable chamber design can ensure that the material is evenly distributed on the liner surface, avoid excessive local wear and thus greatly reduce the wear rate of the liner. With the prolongation of the liner life, the maintenance downtime and liner replacement times are correspondingly reduced. For enterprises, this means lower operating costs. On the one hand, the frequency and cost of purchasing liners are reduced. On the other hand, the production loss caused by shutdown maintenance is reduced, effectively realizing cost control and efficiency improvement.

Due to the reduction of maintenance downtime and liner replacement times, the risk of operators during equipment maintenance and part replacement is also reduced, which greatly improves the safety of equipment operation. At the same time, we also provide special lifting tools specifically for the maintenance of the E-SMG series cone crushers. These tools can ensure the safe, stable lifting and accurate installation of parts during operations such as liner replacement. This not only avoids possible part damage or personal injury caused by improper manual handling but also significantly improves the work efficiency of maintenance and ensures that the equipment can quickly return to normal operation and provide a strong guarantee for the continuous progress of production.

In conclusion, the E-SMG series cone crushers, with their comprehensive wear part product system and significant advantages in selection, performance, cost and maintenance, have become an ideal choice in many crushing operation scenarios and can help enterprises achieve efficient, safe and low-cost production and operation goals.

We are present worldwide and always here to help.

Get in touch today!