Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderClosed side setting (CSS) | Capacity range |

13 mm (0.5 inches) | 615-730 mtph (680-805 stph) |

19 mm (0.75 inches) | 720-900 mtph (795-990 stph) |

25 mm (1 inch) | 915-1210 mtph (1010-1335 stph) |

38 mm (1.50 inches) | 1375-1750 mtph (1515-1930 stph) |

50 mm (2 inches) | 1830-2420 mtph (2015-2670 stph) |

Complete crusher weight | 153,124 kg (337,604 lbs) |

*Note: The processing capacity of the MP1000 cone crusher may vary with different materials and feeding sizes.

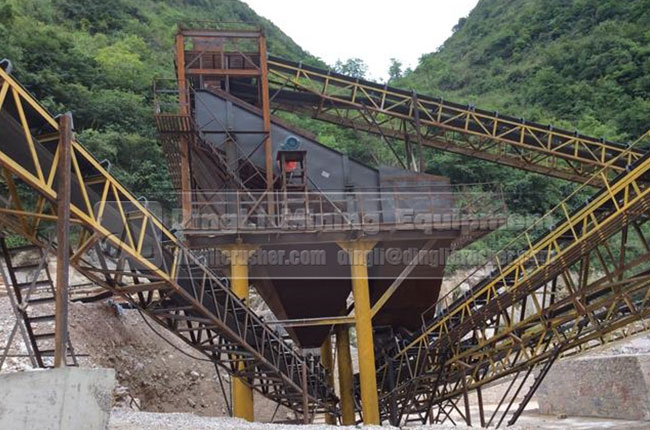

This 2,000 tons of sand and stone production line project is built in the form of EPC general contract, mainly crushing limestone, the use of hammer crusher as the main crushing equipment, the total investment of the project is $3,508,2303.0830, the annual output value is 6 million tons.

In this production sites we get to know all the crushing equipment was orderly installing by our professional technicians.

Machine: ZGC1538 vibrating feeder + PCZ1615 heavy hammer crusher + 4*YKZ2460 vibrating screen + ZSJ 1218 dual rotor sand maker

In the field of cone crushers, the MP1000 stands out with its excellent characteristics.

The MP1000 weighs 153,124 kg (337,604 lbs), which provides a solid foundation for its stable operation. Its production capacity ranges from 615 - 2420 mtph (677 - 2667 stph). Compared with traditional low - output cone crushers, the production capacity advantage is remarkable. Traditional equipment often falls short when facing large - scale production demands. However, the MP1000 can easily handle tasks. Whether it is the crushing of a large amount of ore in a large - scale mine or the material processing of a large - scale construction aggregate project, it can efficiently complete the task, greatly improving production efficiency and reducing the production cycle.

Traditional low - output cone crushers are relatively conservative in design. When processing materials, they have poor adaptability to material characteristics and feeding conditions. The MP1000 is different. It adopts a more advanced design, such as an optimized crushing chamber shape, which can make the material more evenly stressed in the chamber and achieve a better crushing effect. At the same time, its discharge opening adjustment system is more accurate and convenient. According to different production requirements, it can be quickly adjusted to the appropriate discharge size to ensure the production of product particle sizes that meet the requirements.

In terms of structure, the MP1000 is sturdy and durable. Key components have been specially treated, and their wear - resistance is strong, which greatly reduces the failure rate of the equipment. In contrast, due to structural and material limitations, traditional low - output cone crushers are prone to problems such as component wear and looseness after long - term operation, resulting in frequent shutdowns for maintenance. By reducing downtime, the MP1000 ensures the continuity of production and reduces maintenance costs and economic losses caused by production interruptions for enterprises.

The MP1000 cone crusher, with its high production capacity, advanced design, and high reliability, stands in sharp contrast to traditional low - output cone crushers and has become an ideal choice in the modern industrial crushing field.

We are present worldwide and always here to help.

Get in touch today!