Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | PSGD1613 |

| Max feed size | 113 mm |

| CSS Range | 10 - 25 mm |

| Capacity(by hour) | 190 - 336 t/h |

| Motor power | 250 kW |

| Dimensions | 3941×2954×3771 mm |

| Weight | 43870 Kg |

*Note: The processing capacity of the PSGD1613 cone crusher may vary with different materials and feeding sizes.

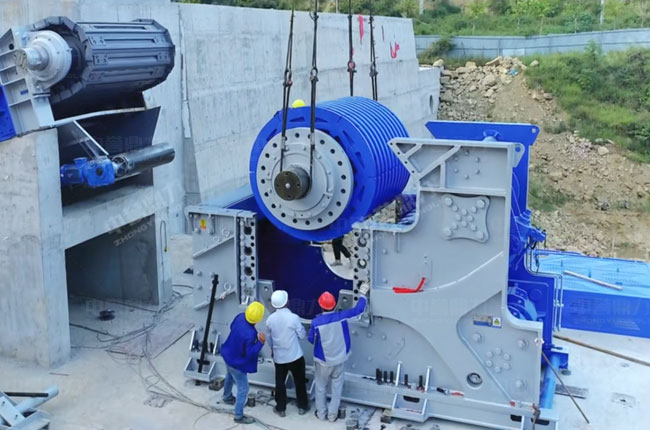

Horizontal rotary crusher for hard rock crushing effect is good, can achieve pre-screening, front extrusion crushing, small wear, automatic hydraulics, encounter iron block automatic pressure, the equipment has a protective effect, compared with the traditional vertical rotary crusher, there will be no cavity mouth blocking phenomenon, but also reduce the investment of the crushing arm.

As a 600tph fine gravel production line in Mangao Huishui Guizhou it can produce about 1000 ton finished stone which is mainly configured with ZG1550 vibrating feeder PCZ1615 heavy hammer crusher*2 ZSJ1218 dual sand shaping machine.

Relying on local river pebble resource the customer invests such a 300tph stone crushing line. Our KPC1313 hard rock crusher adopts the rotor with two rows of hammers so it can fully crush the materials. Hydraulic cylinder pulls the the s

Specification: 5.5'FT

Model: PSGD - 1613

Cavity Type: Short - head Coarse

Large - end Diameter of Crushing Cone: 1676 mm

Discharge Opening Adjustment Range: 10 - 25 mm

Feed Size at the Opening Edge with Recommended Minimum Discharge Opening: 133 mm

Maximum Feed Size: 113 mm

Processing Capacity: 190 - 336 t/h

Power of Main Motor: 250 kW

Machine Weight: 43870 kg

Overall Dimensions: 3941×2954×3771 mm

Powerful Short - head Coarse Crushing: The PSGD - 1613's short - head coarse cavity design, combined with its 1676 - mm large - end diameter of the crushing cone, empowers it to handle relatively large - sized materials effectively. It can break down these materials into coarser particles, making it suitable for primary or secondary crushing in industries like mining, where large - scale processing of ores is required. This design ensures efficient energy utilization during the crushing process, reducing the overall cost per ton of material processed.

Adjustable Discharge for Versatility: The ability to adjust the discharge opening from 10 to 25 mm offers operators the flexibility to control the particle size of the crushed output according to different production needs. In the construction aggregate industry, for example, this can be used to produce coarser aggregates for base layers in road construction or for large - scale building foundations. The flexibility in discharge size allows the crusher to adapt to a wide variety of downstream applications, enhancing its overall utility.

High - capacity Processing for Large - scale Operations: With a processing capacity of 190 - 336 t/h, the crusher is well - suited for large - scale production environments. Whether it's a large - scale quarry operation or a major construction project, the PSGD - 1613 can handle substantial volumes of materials, ensuring a continuous supply of crushed products. This high - capacity processing helps to meet the demands of large - scale projects, reducing the need for multiple crushers or extended processing times.

Stable Power Supply for Consistent Performance: The 250 - kW main motor provides a stable and reliable power source for the crusher. This ensures consistent performance during continuous operation, even when dealing with hard or abrasive materials. The stable power enables the crusher to maintain a consistent crushing force, resulting in a more uniform particle size distribution in the crushed products. This is crucial for maintaining the quality of the end - product, especially in applications where product consistency is highly valued.

Robust and Durable Structure for Long - term Use: Weighing 43870 kg and having a large overall size, the crusher is constructed with a robust and durable structure. It can withstand the high - impact forces and abrasion associated with coarse - crushing operations over an extended period. The durable structure reduces the need for frequent maintenance and replacement of components, minimizing downtime and maximizing the equipment's lifespan. This long - term durability is a significant advantage in industrial settings, where continuous operation is essential for maintaining productivity.

We are present worldwide and always here to help.

Get in touch today!