Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | Φ600 | |

| Model | PYB600 | PYD600 |

| Crusher Cone Diameter at Large End (mm) | 600 | 600 |

| Max Feed Size (mm) | 65 | 35 |

| Discharge Opening Width (mm) | 12-25 | 3-13 |

| Capacity (t/h) | 40 | 12-23 |

| Motor Power (kW) | 30 | 30 |

| Weight (t) | 5 | 5.5 |

| Dimensions (L×W×H) (mm) | 2234×1370×1675 | 2234×1370×1675 |

*Note: The processing capacity of the PYD600 cone crusher may vary with different materials and feeding sizes.

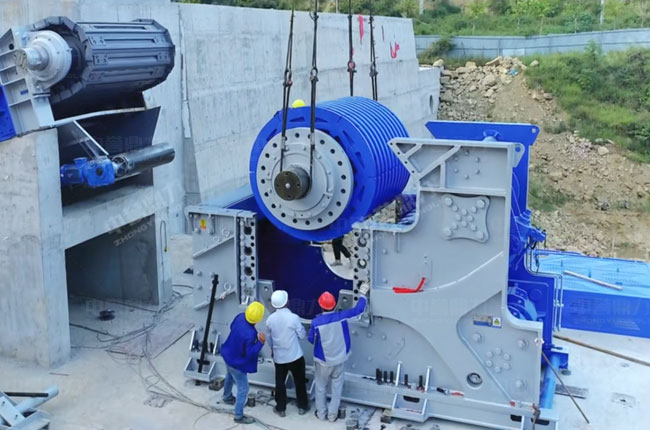

Horizontal rotary crusher for hard rock crushing effect is good, can achieve pre-screening, front extrusion crushing, small wear, automatic hydraulics, encounter iron block automatic pressure, the equipment has a protective effect, compared with the traditional vertical rotary crusher, there will be no cavity mouth blocking phenomenon, but also reduce the investment of the crushing arm.

From the production site different kinds of stones were conveyed from various v-belts that are convenient in dividing materials to apply into different production program.

This production line takes a leading role in the industry with relatively large hourly capacity. With the quality of crushed material meeting relative quality requirements of China such a line can provide qualified aggregates for highway railway.

In industries such as metallurgy, building materials, mining, and chemical engineering, material crushing is a crucial process. The PYD600 cone crusher has become a high - quality option for many enterprises when processing materials of medium and above - medium hardness due to its excellent performance.

When the PYD600 cone crusher is working, the electric motor drives the eccentric shaft sleeve to rotate through an elastic coupling, a transmission shaft, and a pair of bevel gears. The axis of the crushing cone makes a swinging motion under the force of the eccentric shaft sleeve, causing the crushing wall and the mantle to approach and move away from each other. During this process, materials such as iron ore, copper ore, and limestone fed into the crushing chamber are continuously crushed by extrusion, impact, and bending. This working principle ensures the excellent performance of the PYD600 cone crusher in medium and fine crushing operations.

The PYD600 cone crusher has a maximum feed size of 35mm, which is suitable for processing relatively small - sized materials or those that have undergone preliminary crushing. The discharge opening can be flexibly adjusted within the range of 3 - 13mm, precisely meeting the strict requirements of different industries for material particle sizes. Whether it is for the production of construction aggregates or the processing of chemical raw materials, products that meet the standards can be produced by adjusting the discharge opening. Its processing capacity ranges from 5 - 20 tons per hour, which is very suitable for small and medium - sized enterprises. It can ensure production continuity without causing waste of production capacity.

1. Stable and Efficient Production: Equipped with a 30kW motor, the PYD600 cone crusher has strong power, large production capacity, and stable performance. It can maintain high - efficiency operation during long - term continuous work, improving the production efficiency of enterprises. Whether processing relatively hard materials like granite or slightly softer materials like sandstone, it can reliably complete the crushing task.

2. Low Operating Costs: The wearing parts are made of special wear - resistant materials and advanced manufacturing processes, with a long service life. This not only reduces the replacement frequency and maintenance costs but also avoids frequent shutdowns, further reducing operating costs and improving the economic benefits of enterprises.

3. Simple and Quick Maintenance: The continuous oil - supply lubrication system of the thin - oil station continuously lubricates the key components, reducing friction and wear of the parts and lowering the equipment failure rate. At the same time, it extends the maintenance cycle and significantly shortens the shutdown maintenance time, ensuring continuous and stable production.

The PYD600 cone crusher weighs 5.5 tons and has external dimensions of 2234×1370×1675mm. It is flexible to install and use, can be quickly put into use without complex infrastructure construction, and is also convenient to transfer between different sites. If you are in industries such as metallurgy, building materials, mining, and chemical engineering and have the need for medium and fine crushing of materials, the PYD600 cone crusher is definitely a high - quality device worth considering. It can provide an efficient and reliable crushing solution for your enterprise, helping to improve production efficiency and reduce production costs.

We are present worldwide and always here to help.

Get in touch today!