Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | SC160S | |

| Cavity Type | C1 | C2 |

| Feed Opening | 360 mm | 300 mm |

| Max Feed Size | ≤ 290 mm | ≤ 240 mm |

| Min Discharge Size | ≤ 25 mm | ≤ 22 mm |

| Capacity | 125 - 345 t/h | 108 - 305 t/h |

| Motor Power | 160 kW | |

*Note: The processing capacity of the SC160S cone crusher may vary with different materials and feeding sizes.

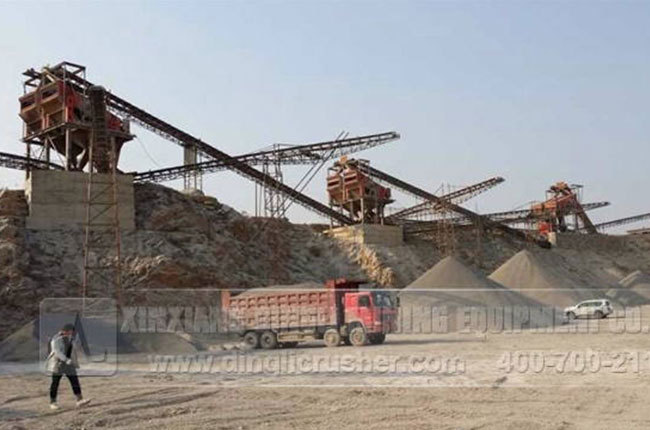

This production line is especially constructed for the building stone with wide application of finished material and optimized operation efficiency.

Production line configuration: DLPCZ1620 heavy hammer crusher DLZG2050 vibrating feeder DL2YKZ2070 vibrating screen*2 sets DL3YKZ3070 vibrating screen*2 sets DL2YKZ3070 vibrating screen DLDMCA deduster*5 sets

This 1400tph production line is configured with 3 sets of vibrating screen running side by side the efficiency of which is 50% higher than that of combined screening of two screens.

The SC160S Single Cylinder Hydraulic Cone Crusher is a high-performance medium crushing machine in the SC series, suitable for industries such as metallurgy, construction, road building, chemistry, and silicate raw material crushing. The SC160S has a maximum feed opening size of 360 mm and a processing capacity range of 125 - 345 t/h, making it ideal for high-capacity medium crushing operations.

The SC160S uses a single hydraulic cylinder to raise and lower the moving cone, achieving multiple functions such as discharge opening adjustment, cavity cleaning, iron passing prevention, and overload protection. It is equipped with an electronic intelligent discharge opening control system, enabling more production process control and operational optimization. The main shaft is supported at both ends, allowing it to withstand greater crushing force and stroke, combined with a special crushing chamber shape adapted to the layer compression principle, which significantly improves crushing efficiency.

The SC160S employs a special crushing chamber shape and layer compression principle, producing particle-to-particle crushing effects. This results in a higher proportion of cubic-shaped products, fewer needle-like and flaky stones, and a more uniform particle size. The internal structure has excellent sealing performance, preventing dust and impurities from entering and extending the equipment's lifespan.

The SC160S offers multiple medium and fine crushing chamber types. By simply replacing the fixed cone, different crushing requirements can be met. The modular design makes the equipment more flexible, allowing for the conversion between coarse, medium, and fine crushing by changing the chamber type, thus improving production efficiency. Overload protection and automatic control functions ensure stable operation under various conditions.

We are present worldwide and always here to help.

Get in touch today!