Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | C100 |

| Feed opening | 760 x 1000 mm |

| Max feed size | 650 mm |

| CSS Range | 70 - 200 mm |

| Capacity(by hour) | 140 - 400 t/h |

| Motor power | 110 kW |

| Dimensions | 3670 x 2420 x 24900 mm |

| Rotation speed of eccentric shaft | 260 r/min |

*Note: The processing capacity of the C100 jaw crusher may vary with different materials and feeding sizes.

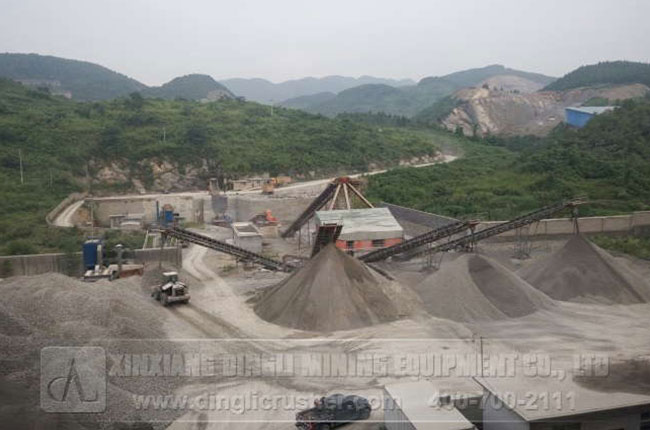

As we can see from the production site the arrayed equipment successively produced numerous finished gravels and then was sent into the cement production projects which has lower production costs.

The pics show actual production site in the following we will continue to improve the production line by configuring more sets of dust collector so as to reach national standard for green mining.

In production ba

The C100 Jaw Crusher is a high-capacity and reliable crushing machine designed and manufactured by our company using advanced foreign technology. This European-style jaw crusher is capable of handling materials with a compressive strength below 320MPa and is widely used in mining, construction materials, cement, metallurgy, road construction, and chemical industries.

The C100 Jaw Crusher operates smoothly without vibration, ensuring stable and reliable performance. This feature minimizes wear and tear on the machine, extending its lifespan and reducing maintenance needs. The advanced design provides a reliable and efficient crushing solution for demanding applications.

The C100 Jaw Crusher features a frameless structure with high-strength wall plates and precision-machined pins, forming a robust chassis that enhances load-bearing capacity. The moving jaw assembly, pulleys, and flywheels are all made from high-quality cast steel or cast iron, providing exceptional durability. The use of high-strength forged eccentric shafts and premium bearings ensures outstanding reliability.

The C100 Jaw Crusher has an optimized chamber design with well-coordinated feed opening dimensions and chamber height. The ratio of the feed opening length to width is carefully tested to maximize material throughput and minimize clogging issues.

The discharge opening adjustment mechanism uses a dual-wedge structure, making it easy and reliable to adjust. This allows users to quickly and conveniently change the discharge opening size, reducing downtime and improving operational flexibility.

We are present worldwide and always here to help.

Get in touch today!