Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | HJC80 |

| Feed opening | 550 x 800 mm |

| Max feed size | 460 mm |

| CSS Range | 70 - 150 mm |

| Capacity(by hour) | 100 - 220 t/h |

| Motor power | 55 kW |

*Note: The processing capacity of the HJC80 jaw crusher may vary with different materials and feeding sizes.

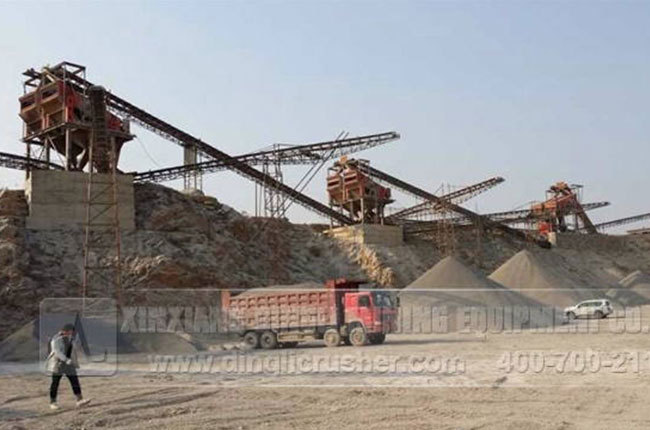

In the production site the material shape can be effectively controlled by each process that has better shape than natural sand. It has a bright future with meeting the demand of sand size gradation and crushing index.

Seen from the picture the monitoring system can clearly monitor every corner of the stone production line. It is part of our whole automatic stone production line.

This 1400tph production line is configured with 3 sets of vibrating screen running side by side the efficiency of which is 50% higher than that of combined screening of two screens.

The HJC80 Jaw Crusher is a high-performance model in the HJC Series Jaw Crushers, designed to handle large rock and hard ore materials. With a maximum feed size of 460 mm, it is an excellent choice for primary crushing applications.

The HJC80 Jaw Crusher has an inlet size of 550 x 800 mm, capable of accepting a wide range of material inputs, enhancing operational flexibility. The adjustable outlet range of 70 - 150 mm provides users with precise control options to ensure the final product meets specific application requirements. This crusher has a production capacity of 100 - 220 t/h, suitable for large-scale operations. Equipped with a 55 kW motor, it ensures efficient power output while considering energy efficiency, achieving both economic and environmental goals.

In terms of design, the HJC80 Jaw Crusher features a heavy-duty moving jaw assembly including high-quality cast steel components, a heavy eccentric shaft, four large self-aligning roller bearings, and a labyrinth seal structure. These components work together to ensure reliable operation under extreme conditions. Additionally, the vibration damping installation design effectively absorbs peak loads from equipment vibrations, reducing noise pollution and minimizing impact on the foundation, thus extending the equipment's service life.

We are present worldwide and always here to help.

Get in touch today!