Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | HJC95 |

| Feed opening | 650 x 950 mm |

| Max feed size | 550 mm |

| CSS Range | 80 - 160 mm |

| Capacity(by hour) | 150 to 280 t/h |

| Motor power | 75 kW |

*Note: The processing capacity of the HJC95 jaw crusher may vary with different materials and feeding sizes.

The coal gangue sand production line can process coal gangue into sand aggregate, which can not only solve environmental pollution, but also make up for the shortage of sand aggregate resources. It is an economic and environmental protection resource utilization mode, which meets the strategic requirements of green sustainable development.

This production line with relatively small capacity is configured with PCZ 1512 heavy hammer crusher. Without adoption of secondary crusher it not only reduces equipment investment but also saves the cost for repair and maintenance.

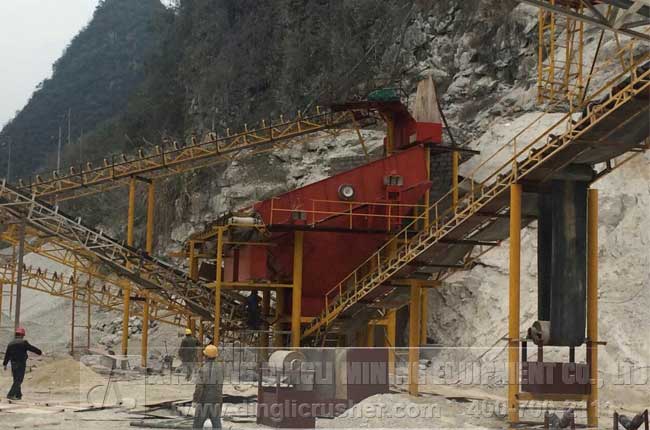

In this aggregates production plant we get to know it builds near mountain for rich local natural resource low transportation energy costs and high productivity.

The HJC95 Jaw Crusher is a high-performance model in the HJC Series Jaw Crushers, designed to handle large rock and hard ore materials. With a maximum feed size of 550 mm, it is an excellent choice for primary crushing applications.

The HJC95 Jaw Crusher has an inlet size of 650 x 950 mm and an adjustable outlet range of 80 - 160 mm, providing operators with the flexibility to adjust the final product size to meet specific requirements. With a production capacity ranging from 150 to 280 t/h, this crusher is ideal for medium to large-scale operations. It is equipped with a 75 kW motor, ensuring efficient energy utilization and reduced operating costs.

To enhance stability and longevity, the HJC95 Jaw Crusher employs an integral cast steel bearing housing design, which ensures perfect alignment between the bearing housing and the frame, avoiding radial loads on the bearing bracket that are common with traditional split bearing housings. Additionally, the integrated protective transmission unit simplifies installation and allows for adjustable V-belt tension, effectively protecting the transmission components and extending the equipment's service life.

We are present worldwide and always here to help.

Get in touch today!