Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | PEW250 x 1200 |

| Feed opening | 250 x 1200 mm |

| Max feed size | ≤ 220 mm |

| CSS Range | 20 -4 0 mm |

| Capacity(by hour) | 20 - 50 tph |

| Motor power | 37 - 45 KW |

| Dimensions | 1400 x 2050 x 1310 mm |

| Weight | 7800 Kg |

| Rotation speed of eccentric shaft | 330 |

*Note: The processing capacity of the PEW250 x 1200 jaw crusher may vary with different materials and feeding sizes.

Nominal capacity12 - 35 tph

Max. feed size≤ 180 mm

Motor power30 - 37 KW

Live ChatNominal capacity12 - 35 t/h

Max. feed size150 mm

Motor power30 kW

Live Chat

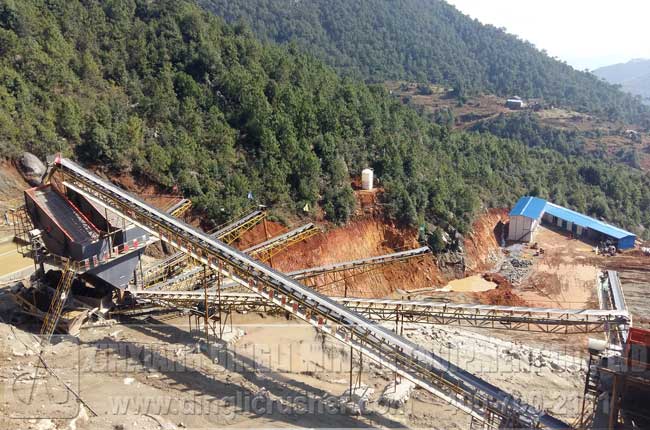

Airplane Construction in Liu Panshui Guizhou chose 300tph aggregates production line. From the picture we get to know it chooses four mineral equipment of PCZ1512 heavy hammer crusher vibrating feeder and two efficient vibrating screens.

The above pictures show production site of hard rock crusher plant. Unlike traditional crushing plant it adopts only one set of hard rock crusher to complete the crushing process which greatly reduces the equipment investment and increase

Four stone crusher plants take initiative to build a large limestone crushing line with the hourly capacity of 4000 ton the scale of which is rare both at home and aborad.

This model has a feed opening size of 250×1200mm and can handle materials up to 220mm in size. Operating at a speed of 330 rpm, the PEW250×1200 can manage capacities between 20 and 50 tons per hour. Weighing approximately 7,800 kg, it is equipped with a hydraulic oil station and lubrication system suited for automated production lines.

Premium Materials: Utilizes FEA technology, with a moving jaw assembly constructed from high-quality cast steel and a heavy-duty eccentric shaft fabricated from forgings.

Enhanced Stability: The integral cast steel bearing housing ensures perfect alignment with the frame, enhancing radial strength and overall structural integrity.

Simplified Adjustments: The discharge opening is adjusted using a hydraulic wedge mechanism, offering ease and speed in adjustments.

Maintenance Convenience: Centralized lubrication system makes maintenance more manageable.

Efficient Crushing: The V-shaped crushing chamber maintains consistent feed size and improves crushing efficiency.

Protective Design: Elbow plates break to prevent damage when non-crushable materials enter the crushing chamber. Hydraulic cylinders provide overload protection by releasing hydraulic oil during overloads.

We are present worldwide and always here to help.

Get in touch today!