Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | CZS84D | |||

| Cavity Type | F | M | C | EC |

| Maximum feed size (mm) | 89 | 113 | 151 | 172 |

| Discharge opening adjustment range (mm) | 5-16 | 10-19 | 13-25 | 16-25 |

| Processing Capacity (t/h) | 190-408 | 354-508 | 454-599 | 508-653 |

| Motor power (kw) | 315 | |||

| Machine weight (t) | 92 | |||

| Overall dimensions(mm) | 4613×3251×4732 | |||

*Note: The processing capacity of the CZS84D cone crusher may vary with different materials and feeding sizes.

1500TPH production line configuration equipment model vibrating feeder ZG2050 crusher PCZ1820 shaping crusher.

In this production line we firstly crushed the huge materials into smaller ones by crusher and then crushed into smaller finished stones by second crushing; lastly we need a sand maker to produce quality sand.

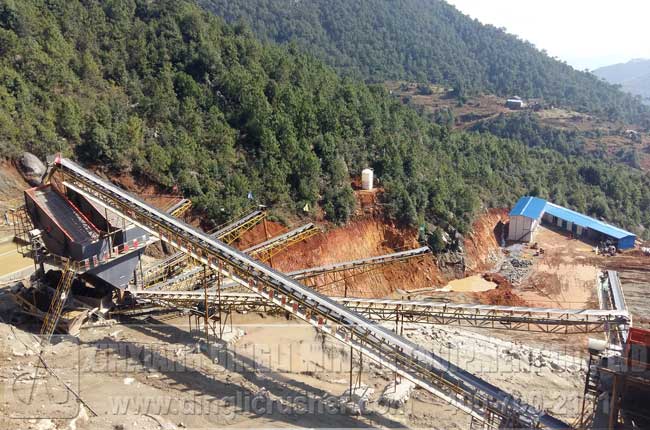

The above pictures show production site of hard rock crusher plant. Unlike traditional crushing plant it adopts only one set of hard rock crusher to complete the crushing process which greatly reduces the equipment investment and increase

The CZS84D cone crusher is a high-performance piece of equipment that offers great value in a variety of industrial settings. Understanding its most suitable applications and knowing how to configure it with other equipment is essential for maximizing its efficiency and productivity.

The F cavity of the CZS84D, with a maximum feed size of 89 mm and a discharge opening adjustment range of 5 - 16 mm, is well-suited for fine aggregate production. In applications like creating sand for high-quality concrete used in precision construction projects, such as high-rise buildings, bridges with strict structural requirements, or decorative concrete elements in architectural designs, its ability to handle moderately sized feed materials and produce a finely crushed output is crucial. With a processing capacity of 190 - 408 tons per hour, it can supply a consistent stream of fine aggregates to meet the demands of medium to large-scale production, ensuring the quality and uniformity of the final concrete products.

The M cavity, which can accommodate a maximum feed size of 113 mm, is a great fit for road and railway construction. When it comes to producing crushed stones for roadbeds, asphalt mixtures, or railway ballast, its 10 - 19 mm discharge opening adjustment range and a processing capacity of 354 - 508 tons per hour allow it to efficiently convert larger rocks into the appropriate sizes. This helps in creating durable and stable surfaces that can withstand heavy traffic loads and the dynamic forces exerted by trains, making it an essential component in transportation infrastructure projects.

For the C cavity, capable of taking in materials up to 151 mm, it is a key asset in heavy-duty mining and quarrying operations. In mining, where large chunks of ore need to be broken down for further processing like smelting or extraction of valuable minerals, and in quarrying to produce various sizes of stones for different construction uses, its 13 - 25 mm discharge opening adjustment range and a processing capacity of 454 - 599 tons per hour enable it to handle significant volumes of materials effectively. It streamlines the initial crushing process and provides a continuous supply of crushed products for subsequent refinement or use.

The EC cavity, with a maximum feed size of 172 mm, is designed for handling larger materials in high-volume processing scenarios. In large-scale mining operations dealing with massive ore deposits or in heavy-duty quarrying where oversized rocks are common, its 16 - 25 mm discharge opening adjustment range and a processing capacity of 508 - 653 tons per hour come into play. It can rapidly reduce these large chunks of materials into more manageable sizes, enhancing the overall productivity of the operation and facilitating the flow of materials through the subsequent stages of processing.

When setting up the CZS84D cone crusher, careful consideration of the associated equipment is necessary for a seamless production process.

Feeding Equipment: The choice of feeding equipment should be based on the crusher's maximum feed size and processing capacity. For the F cavity, a vibrating feeder with a controlled feed rate and a hopper that can hold an appropriate amount of raw materials is recommended to ensure a steady supply of materials within the 89 mm maximum feed size. Similar considerations apply to the other cavities, with the feeder's capacity adjusted accordingly to match the specific maximum feed size and processing requirements of each cavity.

Conveyor System: The conveyor belts used to transport the crushed materials need to be properly sized. Their width and speed should be selected to handle the output of the CZS84D. For example, when the crusher is operating at its higher processing capacities, especially with the C or EC cavities, a wider and faster conveyor belt is required to avoid bottlenecks and ensure smooth transfer of materials to the next stage of the production process, such as screening or storage.

Screening and Sorting Equipment: To obtain the desired final product sizes, screening and sorting equipment are crucial. The mesh sizes of the screens should be carefully chosen based on the discharge opening adjustment ranges of the different cavities. This way, the crushed materials can be effectively separated into different size fractions, allowing for the production of various grades of aggregates or the isolation of materials ready for further processing in mining or other industrial applications.

The CZS84D cone crusher's wide range of applications and the importance of proper configuration with other equipment make it a vital part of many industrial processes. By understanding these aspects, users can make the most of its capabilities and achieve efficient and productive material crushing operations.

We are present worldwide and always here to help.

Get in touch today!