Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | DLDS440 | |

| Cavity Type | S1 (Coarse) | S2 (Medium Coarse) |

| Feed Opening | 450 mm | 400 mm |

| Max Feed Size | ≤ 360 mm | ≤ 320 mm |

| CSS Range | ≤ 35 mm | ≤ 29 mm |

| Capacity | 267 - 605 t/h | 225 - 515 t/h |

| Motor Power | 250 kW | |

*Note: The processing capacity of the DLDS440 cone crusher may vary with different materials and feeding sizes.

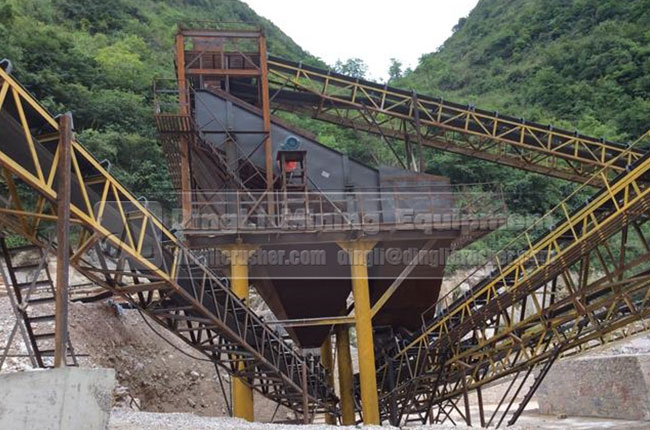

The two production lines can be independent to meet the production needs of off-peak season. The screening and powder selection links adopt highly compact building design to reduce the floor area. The sand washing link has water recycling design to reduce the waste of water resources and reduce the production cost.

Machine: ZGC1538 vibrating feeder + PCZ1615 heavy hammer crusher + 4*YKZ2460 vibrating screen + ZSJ 1218 dual rotor sand maker

2500 Ton/Day Gravel Aggregate Production Process Configuration List Equipment Model Unit(s) Vibrating Feeder ZG1038 1 Heavy Hammer Crusher PCZ1510 1 Hammer Crusher XPC0808 1 Vibrating Screen 2YKQ2060 2 The bulk limestone is evenly fed into

The DLDS440 Single Cylinder Hydraulic Cone Crusher is a high-performance crushing equipment developed by Zhongyu Dingli based on years of industry experience and technical accumulation. This equipment is suitable for the cement, building materials, metal, and non-metallic mineral industries, particularly for processing iron ore, basalt, limestone, and other minerals with hardness below 16. The DLDS440 has a wide range of production capacities, from 267 to 605 tons per hour, making it suitable for large-scale production.

The core advantage of the DLDS440 lies in its unique layered crushing technology. Compared to traditional cone crushers, the DLDS440 uses advanced layered crushing principles, which not only increase production and efficiency but also optimize the shape of the product, ensuring that the finished material is cubic. This design helps reduce energy consumption in subsequent processing and improves the overall economic benefits of the production line.

The DLDS440 is equipped with a spiral bevel gear transmission system, which offers higher load-bearing capacity, smoother operation, and lower noise levels. Additionally, the equipment features an overload protection function, providing a higher pressure margin during normal operation to ensure the reliability of the hydraulic system. When the machine is overloaded, the system will promptly issue an alarm signal to prevent damage to the equipment.

To further enhance the reliability and lifespan of the equipment, the DLDS440 uses a U-T dust seal system and positive pressure dust prevention device, effectively preventing lubricant contamination and protecting the bearings from damage. The bearing lubrication design employs an oil wedge design, forming a lubricating oil film between the shaft and bearing, reducing direct friction, lowering heat generation, and extending the life of the bearings.

The DLDS440 also features a hydraulic and lubrication integrated design, with the hydraulic station and lubrication station designed as one unit, saving installation space and facilitating operation and maintenance. The optimized oil tank capacity uses only one-third of the oil compared to similar hydraulic lubrication stations, significantly reducing daily production costs.

Intelligence is a major highlight of the DLDS440. The equipment is equipped with an automatic control system that provides multiple operating modes, allowing users to flexibly choose according to their production needs. The system continuously monitors the actual load inside the equipment, displaying various operating parameters in real-time. When the liner wears out and becomes unusable, the control panel automatically displays an alarm signal to facilitate timely maintenance.

In summary, the DLDS440 Single Cylinder Hydraulic Cone Crusher stands out with its ultra-large capacity, efficient crushing capability, and stable performance, making it the ideal choice for many industry users.

We are present worldwide and always here to help.

Get in touch today!