Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | HPC-160 | |

| Cavity Type | C | F |

| Feed opening size (mm) | 150 | 76 |

| Discharge opening size (mm) | 13 | 6 |

| Processing capacity (t/h) | 120-240 | 55-180 |

| Motor Power (KW) | 160 | |

| Main Unit Weight (t) | 13 | |

| Movable cone diameter (mm) | 950 | |

*Note: The processing capacity of the HPC160 cone crusher may vary with different materials and feeding sizes.

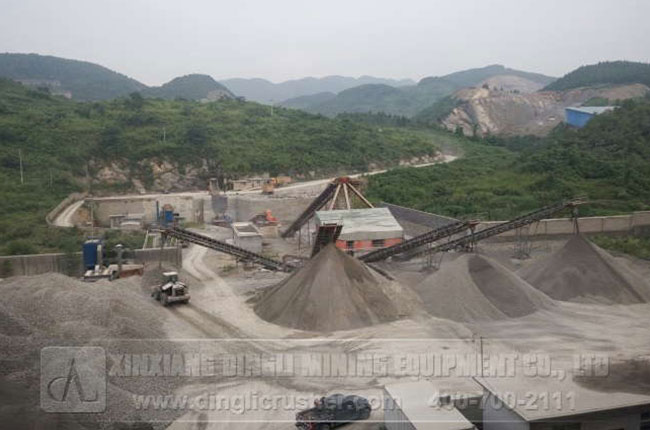

As we can see from the production site the arrayed equipment successively produced numerous finished gravels and then was sent into the cement production projects which has lower production costs.

Basic configuration :We fully consider the matching adaption of material quality and design process of production line through equipment model selection and reasonable configuration.

Investment advantage: the single-line arrangement of crushing process facilitates the transportation. The combined screening of multi vibrating screens makes the material much cleaner.

The HPC-160 cone crusher plays a crucial role in many industries. In the construction industry, it is a core equipment for producing high-quality sand and gravel aggregates. Whether it is for the concrete foundation of high-rise buildings or the paving of roads and bridges, the high-quality sand and gravel produced by it, with good particle shape and gradation, can significantly improve the performance of building materials and ensure the stability and durability of the project. In the field of mine exploitation, for the refined processing of some small mines or specific ore types, the HPC-160 can efficiently crush the ore to the appropriate particle size to meet the requirements of subsequent beneficiation and smelting processes, improve the metal recovery rate and purity, and reduce production costs. In the chemical industry, for the crushing of some chemical raw materials with moderate hardness, such as gypsum and limestone, the HPC-160 can precisely control the discharge particle size to provide uniform and stable raw materials for the production of chemical products, ensure the smooth progress of the chemical production process, and improve product quality.

This crusher is suitable for a variety of common ores and rock materials. For granite with high hardness, the HPC-160, with its powerful crushing force and optimized chamber design, can effectively crush it into the required particle size to meet the demand for granite aggregates in building decoration, road paving and other fields. Basalt, as a high-quality building material with high hardness, can also be easily handled by the HPC-160, and the crushed basalt is widely used in railway ballast, asphalt concrete aggregates and other aspects. In terms of metal ores, the crushing of iron ore is one of the important application scenarios of the HPC-160. By crushing, it provides an appropriate raw material particle size for the subsequent beneficiation process to improve the grade of iron concentrate. In addition, for non-metallic ores such as limestone and quartzite, the HPC-160 can also accurately adjust the discharge opening size according to different production requirements to produce high-quality raw materials that meet the requirements of the chemical, glass manufacturing, ceramic and other industries, demonstrating its wide material adaptability and efficient crushing ability and providing strong support for the development of various industries.

We are present worldwide and always here to help.

Get in touch today!