Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | HPC500 | ||||

| Cavity Type | F2 | F1 | M | C1 | C2 |

| Maximum feed size (mm) | 95 | 135 | 210 | 290 | 330 |

| Minimum discharge opening (mm) | 13 | 16 | 22 | 30 | 38 |

| Processing Capacity (t/h) | 220-430 | 280-455 | 345-605 | 405-790 | 445-855 |

| Motor power (kw) | 400 | ||||

| Machine weight (t) | 37 | ||||

| Overall dimensions(mm) | 3447×2830×2977 | ||||

*Note: The processing capacity of the HPC500 cone crusher may vary with different materials and feeding sizes.

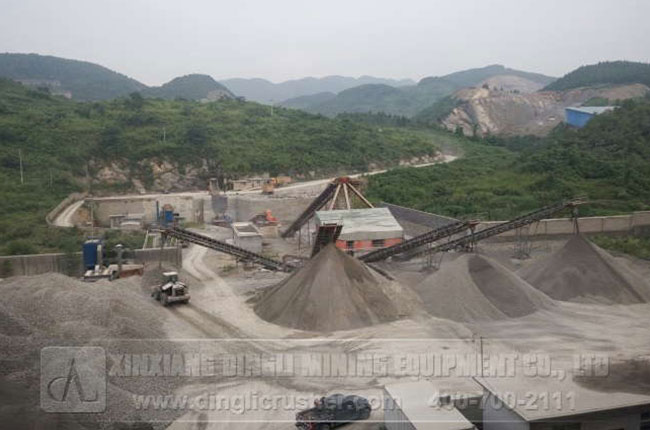

From this site we get to know this production line builds with mountain that can make fully use of limestone. All the machines are installed and provided by Xinxiang Dingli with high matching.

In the production site of customer it can be seen that the raw materials of sand making are mainly the stones with large grain size and through being crushed these stones are finally used for sand making.

As we can see from the production site the arrayed equipment successively produced numerous finished gravels and then was sent into the cement production projects which has lower production costs.

In the realm of modern industry, the HPC500 cone crusher has emerged as a highly advanced and indispensable asset, boasting a wide array of applications across diverse sectors.

Within mining operations, the HPC500 takes center stage right from the start of the extraction process. Its C1 and C2 cavity types are engineered to handle truly colossal feed sizes, with maximums of 290 mm and 330 mm respectively. This allows them to effortlessly break down mammoth chunks of ore, streamlining the initial crushing stage. By reducing the ore to more manageable pieces, it sets the perfect foundation for subsequent processes like grinding and beneficiation. In a gold mine, for instance, the HPC500 can rapidly process vast quantities of ore, guaranteeing a consistent supply of crushed material for further extraction of the precious metal. This not only accelerates the overall mining workflow but also curtails the strain on downstream equipment, leading to remarkable enhancements in productivity and significant cost savings.

When it comes to construction projects, the HPC500 is a paragon of reliability for generating top-notch aggregates. The F1 and F2 cavities prove their worth here. The F1 cavity, featuring a maximum feed size of 135 mm and a processing capacity spanning 280 - 455 t/h, is adept at producing aggregates that meet the demands of a vast spectrum of building applications. From erecting the foundations of towering skyscrapers to constructing humble residential pathways, it delivers the goods. Meanwhile, the F2 cavity, with its finer output capabilities (maximum feed size 95 mm and processing capacity 220 - 430 t/h), is tailor-made for concocting specialized concrete mixes utilized in ornamental elements or high-precision architectural feats. The unwavering consistency in the quality of the aggregates churned out by the HPC500 underpins the structural integrity and longevity of buildings, making it the preferred choice for discerning contractors.

In the construction of roads, highways, and bridges, the HPC500 cone crusher reigns supreme. The M cavity, armed with the capacity to handle larger feedstock (maximum feed size 210 mm) and produce medium-grade aggregates at a processing capacity of 345 - 605 t/h, is an ideal fit for this domain. These aggregates form the bedrock of the road infrastructure, endowing it with the requisite strength and stability. Whether it's a small-scale rural road rehabilitation or a large-scale interstate highway expansion, the HPC500 can furnish precisely the right-sized aggregates in copious quantities, ensuring the seamless progression of construction and the enduring performance of the road network.

Beyond the realms of mining and construction, the HPC500 finds its niche in numerous industrial sectors engaged in materials processing. In the ceramics and refractories industries, for example, the precise manipulation of feed size and discharge opening is non-negotiable. The diverse cavity options of the HPC500 empower manufacturers to fabricate materials with the exact particle size distribution their products demand. This level of precision is instrumental in elevating the quality of the end products, slashing waste, and supercharging production efficiency. Similarly, in the production of industrial abrasives, the crusher can sculpt raw materials into the desired grit sizes, facilitating the creation of high-performance abrasives deployed in metal finishing and surface treatment.

In conclusion, the HPC500 cone crusher's extensive applications in mining, construction, road building, and industrial materials processing bear witness to its adaptability and engineering brilliance. It remains a linchpin in the development and triumph of countless projects, furnishing the essential material transformation capabilities that industries depend on.

We are present worldwide and always here to help.

Get in touch today!