Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | HPC300 | ||||

| Cavity Type | F2 | F1 | M | C1 | C2 |

| Maximum feed size (mm) | 80 | 105 | 150 | 210 | 230 |

| Minimum discharge opening (mm) | 10 | 13 | 16 | 20 | 25 |

| Processing Capacity (t/h) | 110-240 | 130-260 | 175-320 | 190-380 | 220-440 |

| Motor power (kw) | 250 | ||||

| Machine weight (t) | 18.1 | ||||

| Overall dimensions(mm) | 2725×2110×2182 | ||||

*Note: The processing capacity of the HPC300 cone crusher may vary with different materials and feeding sizes.

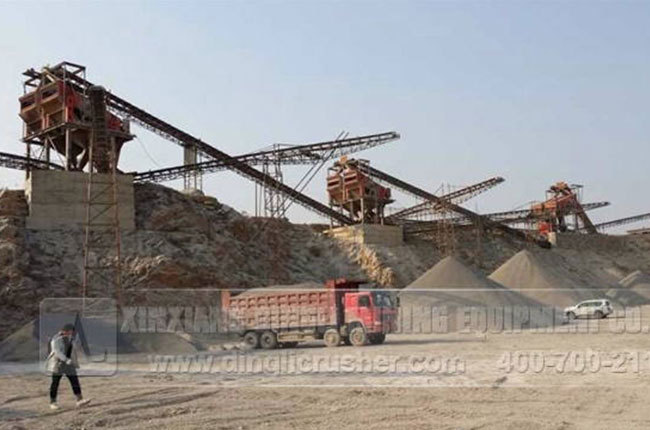

This small gravel aggregates production line built by Dingli has reached our expected hourly capacity.

At the production site it is seen that the material can be crushed into sound grain shape after successively crushing of large heavy hammer crusher and shaping crusher. Our shaping crusher has sound effect in optimizing grain shape.

This 1400tph production line is configured with 3 sets of vibrating screen running side by side the efficiency of which is 50% higher than that of combined screening of two screens.

The HPC300 cone crusher is a remarkable piece of equipment that enjoys wide application in industries handling medium to high-hardness materials. Although it is equipped with multiple cavity types, namely F2, F1, M, C1, and C2, each possessing unique feed and discharge size specifications, this text will zero in on its fundamental working principle.

Powered by a robust 250 kW motor, the generated driving force is smoothly transmitted to an eccentric shaft. Once the motor sets the shaft in rotation, it instigates a precisely controlled gyratory motion of the movable cone, known as the mantle, within the stationary cone, referred to as the concave. This rotational movement of the eccentric shaft is the initial impetus that kick-starts the entire crushing process.

Raw materials are introduced into the crusher via an inlet. It's important to note that the size of this inlet is adaptable, varying in accordance with the particular cavity selected to suit the specific task requirements. Upon entry, the materials make their way into the crushing chamber, which serves as the arena where the transformation from bulky feedstock to finely crushed product commences.

Inside the crushing chamber, the mantle, driven by the eccentric shaft, executes its gyratory motion. This action subjects the materials to intense and repetitive compressive forces that act from multiple directions. By capitalizing on the inherent natural cleavage planes present within the materials, the crusher is able to break them down in a progressive and efficient manner. This process is highly optimized to ensure maximum reduction of particle size while consuming minimal energy.

As the materials undergo successive stages of the crushing and reach the desired fineness, they begin to move downward under the force of gravity. The crushed materials then exit the crusher through the minimum discharge opening, whose dimensions are also cavity-dependent. This continuous cycle of feeding, crushing, and discharging enables the HPC300 to handle substantial volumes of materials. The processing capacity spans from 110 - 240 t/h for the F2 cavity up to 220 - 440 t/h for the C2 cavity, contingent upon the prevailing operating conditions.

In summary, the working principle of the HPC300 cone crusher pivots around the efficient translation of the motor's power into the compressive forces requisite for fracturing materials. This mechanism empowers it to assume a crucial role in a diverse array of material processing applications, making it an indispensable asset in modern industrial settings.

We are present worldwide and always here to help.

Get in touch today!