Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | HPT400 | ||||

| Cavity Type | C1(Super Coarse) | C2(Coarse) | M(Medium) | F1(Fine) | F2(Ultra - Fine) |

| Feed Opening | 295mm | 251mm | 196mm | 110mm | 90mm |

| Minimum Discharge Opening | 30mm | 25mm | 20mm | 13mm | 10mm |

| Processing Capacity | 300 - 630t/h | 285 - 560t/h | 250 - 490t/h | 180 - 345t/h | 135 - 320t/h |

| Maximum Installed Power | 315kW | ||||

*Note: The processing capacity of the HPT400 cone crusher may vary with different materials and feeding sizes.

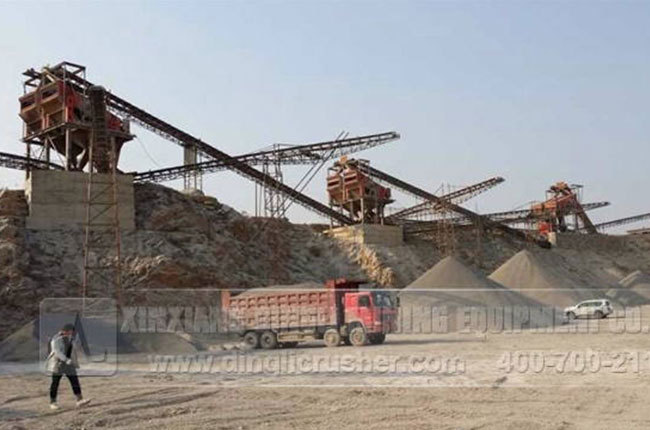

At the production site it is seen that the material can be crushed into sound grain shape after successively crushing of large heavy hammer crusher and shaping crusher. Our shaping crusher has sound effect in optimizing grain shape.

In this 200tph production line in Tengchong Yunnan it can produce 121305 stone and has a good selling in construction market especially 13 stone.

This 1400tph production line is configured with 3 sets of vibrating screen running side by side the efficiency of which is 50% higher than that of combined screening of two screens.

The HPT400 crusher is designed with a variety of cavity types to meet diverse crushing requirements. The C1 (super - coarse) cavity has a feed opening of 295mm and a minimum discharge port of 30mm, with a processing capacity ranging from 300 - 630t/h. The C2 (coarse) cavity, with a 251mm feed opening and 25mm discharge port, can handle 285 - 560t/h. For the M (medium) cavity, having a 196mm feed opening and 20mm discharge port, the capacity is 250 - 490t/h. The F1 (fine) cavity, with an 110mm feed opening and 13mm discharge port, can process 180 - 345t/h. The F2 (ultra - fine) cavity, with a 90mm feed opening and 10mm discharge port, has a capacity of 135 - 320t/h.

Powered by 315kW, the HPT400 is a force to be reckoned with. Its advanced mechanical and hydraulic systems work in harmony to convert this power into efficient crushing force. The different cavity settings are optimized to make the most of the power, ensuring high - quality output across a wide range of particle sizes. This efficient utilization of power allows for seamless operation and high productivity.

The HPT400's design is a balance between sturdiness and space - efficiency. Its construction materials are of high - quality, enabling it to withstand the intense pressures and abrasion during the crushing process. Despite its high - capacity performance, it is designed to fit into various production layouts without occupying excessive space. This makes it a practical choice for both large - scale industrial plants and more compact crushing operations.

This crusher is capable of handling a vast array of materials. From the hardest granite to the more malleable limestone, the HPT400 can crush them effectively. The multiple cavity types provide the flexibility to adapt to different material characteristics and desired output sizes. For instance, the C1 and C2 cavities are excellent for initial size reduction of large - sized materials, while the F1 and F2 cavities are ideal for achieving finer particle sizes for more specialized applications.

The HPT400 incorporates the latest in crusher technology. It features a fixed spindle and a rotating eccentric sleeve structure, which, combined with the laminated crushing principle, significantly enhances the crushing performance. The hydraulic lubrication system not only ensures smooth operation but also provides intelligent control, allowing for precise adjustments and optimal crushing conditions.

Equipped with an automatic hydraulic safety system, the HPT400 can quickly respond to the presence of non - crushing materials. The safety cylinder's oil circuit, with its large - diameter pipes and large - capacity accumulators, offers excellent buffering capabilities. Additionally, the integrated PLC control system continuously monitors the crusher's operation, displaying key parameters and providing timely warnings. This advanced control system simplifies the operation process, reduces the need for manual intervention, and enhances overall safety and efficiency.

The use of spiral bevel gears in the HPT400's transmission system provides efficient and stable power transfer. These gears have a high arc overlap coefficient, resulting in smooth operation, low noise levels, and high load - bearing capacity. The crusher also features enhanced sealing mechanisms, including contact - type spherical floating seals. These seals, in addition to the existing positive - pressure dust prevention and U - T - type seals, ensure the cleanliness of the lubricating oil and improve the stability of the equipment during operation.

We are present worldwide and always here to help.

Get in touch today!