Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | S155B | |||

| Cavity Type | F | M | C | EC |

| Maximum feed particle size (mm) | 109 | 188 | 216 | 238 |

| Minimum discharge opening size (mm) | 13 | 16 | 19 | 25 |

| Processing capacity (t/h) | 109-181 | 132-309 | 172-378 | 236-455 |

| Motor Power (KW) | 185 | |||

*Note: The processing capacity of the S155B cone crusher may vary with different materials and feeding sizes.

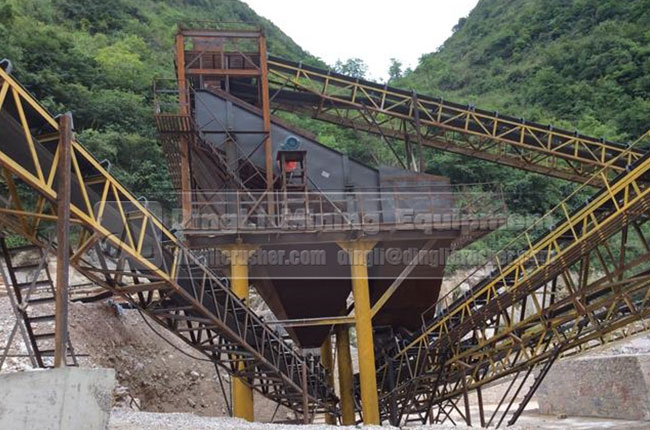

This production line has ZG1538 vibrating feeder PCZ1615 heavy hammer crusher 3YKZ2670 vibrating screen*2 2YKZ2670vibrating screen*2

Machine: ZGC1538 vibrating feeder + PCZ1615 heavy hammer crusher + 4*YKZ2460 vibrating screen + ZSJ 1218 dual rotor sand maker

In Zhongyu Dingli production sites workers orderly installed equipment for 500tph capacity and 5 finished materials with three best sold finished material.

In today's industrial production, which increasingly pursues green and sustainable development, the S155B cone crusher has become a remarkable star in the field of environmental protection with its advanced design and excellent performance.

From the perspective of dust treatment, which is a crucial environmental protection indicator, the S155B cone crusher demonstrates unique advantages. Its overall structure adopts an advanced sealing design concept. At the feed opening, discharge opening, and the connection gaps of various parts of the machine body, high-quality sealing strips and gaskets are equipped, forming a tight sealing system. This design effectively blocks the overflow of dust during the crushing process, minimizing the spread of dust to the surrounding environment.

Meanwhile, this crusher is also equipped with an intelligent and efficient dust removal system. This system, through the suction ports reasonably distributed around the crushing chamber, utilizes the strong suction force generated by the blower to suck in the dust produced during the crushing process in a timely manner. The inhaled dust will be transported to a special dust removal device and undergo multi-layer filtration and purification treatment, significantly reducing the dust content in the discharged gas, meeting or even exceeding the requirements of national environmental protection standards.

During the operation of the equipment, the automatic control system of the S155B cone crusher can also monitor the generation of dust in real-time and automatically adjust the working parameters of the dust removal system according to the actual working conditions, ensuring that the dust removal effect is always maintained at the best state. This not only greatly reduces the air pollution caused by dust, improves the environmental quality of the workplace, and protects the health of operators but also reduces the potential harm of dust to surrounding equipment, vegetation, and soil, realizing the control of dust pollution throughout the process from the source to the discharge. It fully reflects its careful design and innovative practice under the concept of environmental protection, setting a new benchmark for the green development of the industrial crushing field.

We are present worldwide and always here to help.

Get in touch today!