Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | SCS800 | ||||

| Cavity Type | EC | C | M | F | EF |

| Discharge opening range (mm) | 300 | 240 | 155 | 90 | 80 |

| Minimum discharge opening size (mm) | 22-70 | 19-70 | 19-70 | 13-44 | 10-44 |

| Processing Capacity (t/h) | 448-1331 | 406-1286 | 400-1098 | 357-718 | 280-669 |

| Maximum Installed Power (kw) | 630 | ||||

| Weight (excluding motor, in tons) | 68 | ||||

*Note: The processing capacity of the SCS800 cone crusher may vary with different materials and feeding sizes.

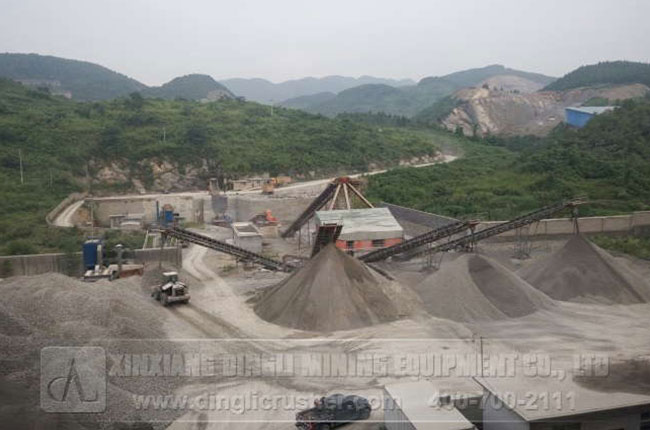

This 300t/h production line basically configured with PCZ1512 heavy hammer crusher ZG1238 vibrating feeder 2YK1860 vibrating screen*3 sets.

Dingli Mining Corporate was recommended by one of my friends. It is surprise that Dingli machines dont let us down with high production effect fine finished material shape and stable operation.

As we can see from the production site the arrayed equipment successively produced numerous finished gravels and then was sent into the cement production projects which has lower production costs.

The SCS800 cone crusher represents a pinnacle of engineering in the field of material reduction. It is designed to handle large volumes of materials with high efficiency and precision, making it an indispensable asset in various industrial sectors.

This crusher features five distinct cavity types - EC, C, M, F, and EF, each engineered to meet specific crushing requirements. The EC cavity offers a discharge opening range of 300 mm and a minimum discharge opening size from 22 to 70 mm. This allows it to process bulky materials while providing flexibility in achieving the desired output size. The C cavity, with a 240 mm discharge opening range and a minimum discharge opening size of 19 to 70 mm, is well-suited for a wide range of applications, ensuring consistent and reliable performance.

The M cavity, having a discharge opening range of 155 mm and a minimum discharge opening size of 19 to 70 mm, is designed to produce finer crushed materials. The F cavity, with a 90 mm discharge opening range and a minimum discharge opening size between 13 and 44 mm, is optimized for applications that demand a more precise particle size. The EF cavity, featuring an 80 mm discharge opening range and a minimum discharge opening size of 10 to 44 mm, is ideal for achieving the finest possible output, catering to industries with strict particle size requirements.

The SCS800 showcases remarkable processing capacities. The EC cavity can handle between 448 and 1331 tons per hour, enabling it to meet the demands of high-volume production. The C cavity has a processing capacity ranging from 406 to 1286 tons per hour, providing a reliable option for large-scale operations. The M cavity is capable of processing materials at a rate of 400 to 1098 tons per hour, while the F cavity can manage between 357 and 718 tons per hour. The EF cavity offers a processing capacity of 280 to 669 tons per hour, suitable for applications where a more controlled and precise output is needed.

The SCS800 operates on the principle of compression. As the material enters the crusher through the feed opening, it is directed into the crushing chamber. Here, the mantle, which rotates eccentrically within the concave liner, exerts a powerful compressive force on the material. This continuous compression action fractures the material, reducing it to the desired particle size. The adjustable discharge opening allows operators to precisely control the size of the crushed output, ensuring it meets the specific needs of the application.

1. High Efficiency: With its powerful motor and optimized crushing chamber design, the SCS800 can process materials at a rapid pace, significantly increasing production output.

2. Versatility: The five cavity types enable it to handle a diverse range of materials, from hard rocks to softer ores, and produce various particle sizes, making it suitable for multiple industries such as mining, construction, and aggregate production.

3. Precision Control: The adjustable discharge opening and different cavity options provide precise control over the final product size, ensuring high-quality and consistent output.

4. Durability: Built with high-quality materials and a robust construction, the SCS800 can withstand the rigors of continuous operation, reducing maintenance requirements and ensuring a long service life.

The SCS800 is powered by a motor with a maximum installed power of 630 kw, providing the necessary energy to drive the crushing process efficiently. In terms of weight, excluding the motor, the crusher weighs 68 tons. This substantial weight contributes to its stability during operation, minimizing vibrations and ensuring accurate and consistent crushing results.

In conclusion, the SCS800 cone crusher combines its advanced cavity design, impressive processing capacities, reliable working principle, and multiple advantages to offer a top-notch solution for material crushing. It is a testament to modern engineering, enabling industries to achieve their production goals with efficiency and precision.

We are present worldwide and always here to help.

Get in touch today!