Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Cavity Type | Cavity | Feed opening (mm) | Maximum feed (mm) | Discharge port (mm) | Motor power (kw) | Main Unit Weight (kg) | Processing capability (t/h) |

| XGP100 | A | 150 | 120 | 7 - 39 | 90 | 5800 | 35 - 135 |

| B | 130 | 105 | |||||

| C | 100 | 85 |

*Note: The processing capacity of the XGP100 cone crusher may vary with different materials and feeding sizes.

Since there is a large quantity of fine-grained particle in the material the pre-screening shall be conducted before secondary and fine crushing. If the particle size is small the closed screening should be adopted.

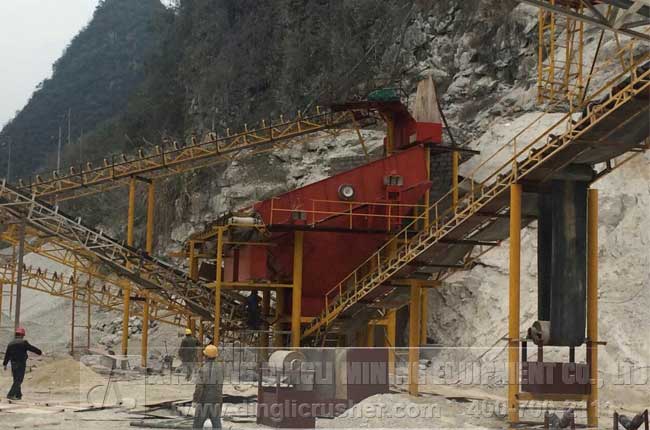

In this aggregates production plant we get to know it builds near mountain for rich local natural resource low transportation energy costs and high productivity.

At the production site it is seen the overall stone production can be completed with only a set of crusher.

The XGP100 Single Cylinder Hydraulic Cone Crusher is designed for efficient medium and fine crushing of various materials such as limestone, quartzite, and coal gangue. It is widely used in sand and gravel plants, mining, coal mining, concrete mixing stations, dry mortar, power plant desulfurization, and quartz sand production.

Optimized Design: The XGP100 features a robust and optimized design, ensuring higher structural strength and more reliable operation.

Efficient Crushing Chamber: The advanced crushing chamber design maintains high layer compression efficiency, even as the liner wears down.

Multiple Cavity Options: The fully automatic control system offers manual control, automatic load, automatic discharge, and dual automatic discharge modes, providing flexibility for different applications.

Integrated Hydraulic and Lubrication System: The hydraulic system is designed to meet standard pressure requirements with a high-pressure margin, enhancing system reliability.

We are present worldwide and always here to help.

Get in touch today!