Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | 300 x 175 |

| Max feed size | 137.5 mm(5.5″) |

| Rotation speed of eccentric shaft | 365/400 R.P.M. |

*Note: The processing capacity of the 300 x 175 jaw crusher may vary with different materials and feeding sizes.

Nominal capacity

Max. feed size1000 mm

Motor power200 KW

Live ChatNominal capacity400 - 800 tph

Max. feed size1020 mm

Motor power200 KW

Live ChatNominal capacity200- 500 tph

Max. feed size720 mm

Motor power132 KW

Live Chat

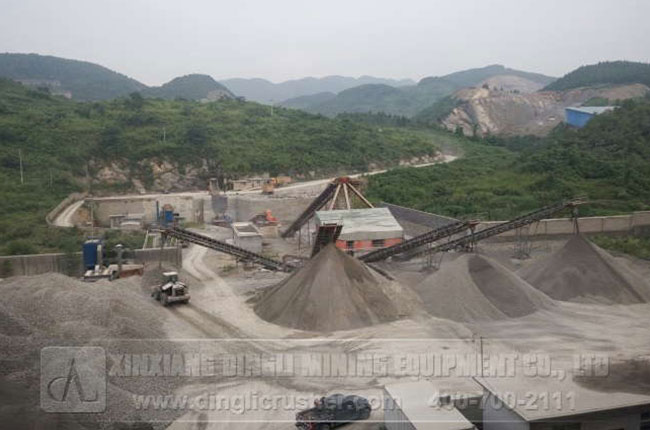

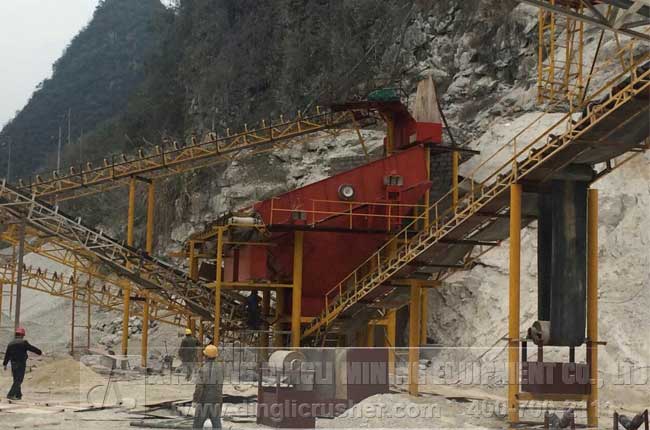

As we can see from the production site the arrayed equipment successively produced numerous finished gravels and then was sent into the cement production projects which has lower production costs.

Machine: ZG1238 vibrating feeder + PCZ1512 heavy hammer crusher + 3YKQ2470 vibrating screen + 2YKQ2470 vibrating screen

In this aggregates production plant we get to know it builds near mountain for rich local natural resource low transportation energy costs and high productivity.

The structural design of 300 x 175 jaw crushers determines their performance. Here are some key structural elements:

The structural design of jaw crushers forms the foundation of their efficient operation.

Moving and Fixed Jaws: The moving and fixed jaws form a crushing chamber where materials are compressed.

Eccentric Shaft: The rotating eccentric shaft generates crushing force, ensuring consistent crushing results.

Adjustment Device: Allows for the adjustment of the discharge opening size to meet different particle size requirements.

Drive System: Including motors and pulleys, the drive system provides the necessary power.

Base Frame: A sturdy base frame ensures stable operation.

The structural design enables 300 x 175 jaw crushers to operate reliably under various conditions.

We are present worldwide and always here to help.

Get in touch today!