Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | GFP250 x 400 |

| Feed opening | 250 x 400 mm |

| Max feed size | 225 mm |

| CSS Range | 8 - 30 mm |

| Capacity(by hour) | 8 - 30 tph |

| Motor power | 15 kW |

| Rotation speed of eccentric shaft | 330 rpm |

*Note: The processing capacity of the GFP250 x 400 jaw crusher may vary with different materials and feeding sizes.

Nominal capacity200- 500 tph

Max. feed size720 mm

Motor power132 KW

Live Chat

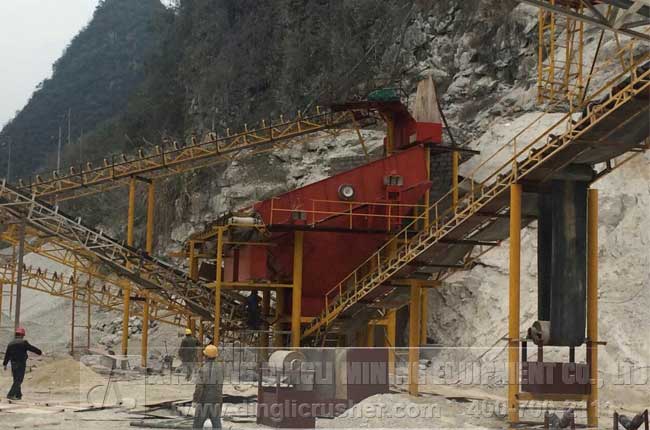

After conducting measure for many times we have designed a reasonable and compact production line; besides we reduced customers’ costs and ensured their output by replacing traditional jaw crusher and impact crusher with hammer crusher.

This small gravel aggregates production line built by Dingli has reached our expected hourly capacity.

In this aggregates production plant we get to know it builds near mountain for rich local natural resource low transportation energy costs and high productivity.

The GFP250 x 400 deep chamber jaw crusher is a compact yet powerful secondary crushing unit commonly paired with PF jaw crushers in stone and sand production lines. It is also suitable for primary crushing applications. Designed to handle materials like limestone, shale, basalt, river pebbles, quartzite, magnetite, basalt, steel slag, and iron ore, this machine excels in crushing hard materials and is widely used in mining, metallurgy, construction, highways, water conservancy, and other sectors.

With a maximum feed size of ≤225mm and a discharge setting range of 8 to 30mm, the GFP250 x 400 can achieve a processing capacity of 8 to 30 tons per hour. The crushing ratio is approximately 15, and the toggle plate oscillates at a rate of 330 times per minute. Equipped with a 15kW motor, this machine is energy-efficient and capable of handling challenging materials effectively.

We are present worldwide and always here to help.

Get in touch today!