Advantages of Reversible Hammer Crusher

Reversible hammer crusher is upgraded on the bases of hammer crusher. By crushing the material with medium hardness into required size for once, it is quite preferred by the customers. Today we would like to make an analysis on its advantages compared with hammer crusher.

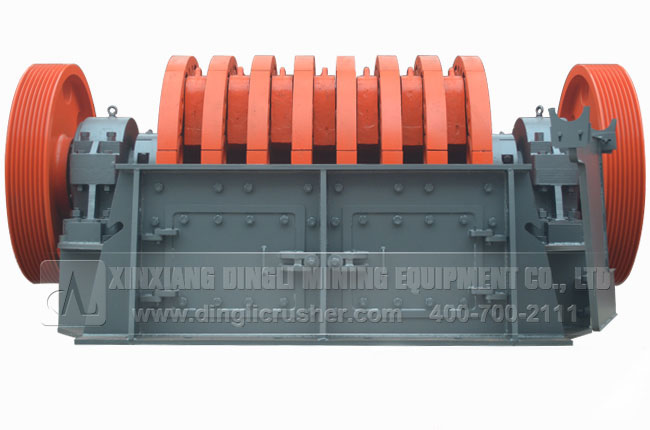

Reversible Hammer Crusher

Corrugated plate is added in the endophragm of cavity so as to impact the material crushed and grinded by the hammers. With such design, the crusher has less energy consumption and abrasion of spare parts including hammers ad lining plate. The operation principle with iron hitting stone and stone hitting stone greatly improves the crushing ratio and capacity of equipment.

Long Service Life

The 360°-rotating rotor is the core part for reversible hammer crusher. In case of abrasion out of long-term operation, the equipment can continue to work after entire rotation of rotor instead of turn-over of the hammers, which not only saves time to replace hammers but also prolongs its use life.

Dry-Wet Application

The adjustable lining plate and spring are applied to control the discharge size, reducing abrasion and damage to the equipment. It can crush the wet material with 15% water content, which means we can add some water into the material so as to avoid dust emission. Compared with traditional hammer crusher, such method is more eco-friendly.

With the advancement of technology and development of crushing industry, hammer crusher has been gradually improved in order to adapt to the fierce competition of gravel production industry. As a leading enterprise engaged in manufacturing hammer crushers, Xinxiang Dingli has attracted nationwide customers to come for visit by offering reliable equipment and reasonable configuration plan.