Limestone Crusher Installation and Maintenance

Dingli integrates research, production, and sale into mining machine of crusher, sand maker, and dust collector for providing the full crushing machine and production line machines for customers. The machines mainly are used in mining, building material, road, bridge, chemical, refractory, and metallurgy.

In production line using and building, there are indispensable problems in mining machine installation and maintenance. Then we will introduce you mining crusher installation and maintenance ways for longer service life.

Limestone crusher machine commissioning

1. Hammer crusher have been adjusted before selling, if you want to change hammerhead or rotor, there should have difference of less than 0.5kg.

2. Strong installation foundation for machine and motor placing.

3. Balance machine installation.

4. Adjust belt losing condition.

5. Fasten bolts.

6. Check wire condition incase having opposition machine motivation.

7. Check grid, rotor, and machine place.

Wear condition of limestone mining crusher:

1. Material

Material content of water and soil will influence crusher machine service life. And the material discharging size and crushing rates will influence machine wear condition.

2. Installation place

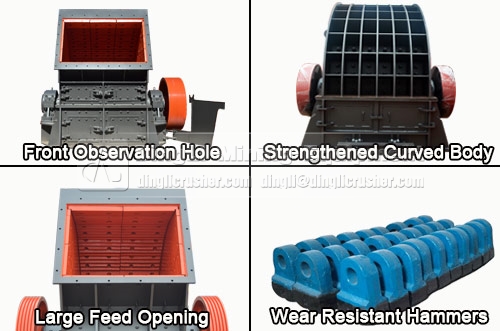

There are hammerhead and hammer handle in hammer crusher. Hammerhead is made by high chrome steel with higher service life. But higher rotating speed will influence crusher machine wear condition.

3. Crusher machine spare parts weight and quality

Crusher hammerhead will influence crusher efficiency, production capacity, energy consumption, and hammerhead wear condition. The weight of hammerhead should crush material into demanded size once and will determine machine energy consumption.

Crusher machine maintenance

1. Check hammerhead wear condition and gap.

2. Change liner.

3. Clean dust on the machine and spare parts.

4. Check crusher device and lubricate them.

5. Clean main parts.

Dingli provides you service of installation, training, technology, maintenance, and commissioning. In installation and commissioning, we have staff for that until reaching your demand. Dingli trains technicians for you free with machine maintenance and using ability.