Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Specification | Details |

|---|---|

| Nominal capacity | 116 - 646 mtph (128 - 712 stph) |

| Max. feed size | 321.0 mm (12.6 in.) |

| Motor power | 315 kW (422 hp) |

| Closed side setting (CSS) range | 10.0 - 51.0 mm (0.4 - 2.0 in.) |

| Eccentric throw range | 18.0 - 50.0 mm (0.7 - 1.9 in.) |

| Mantles (inner liners) | A, B, HC, EF, HC, D, FF |

| Concaves (outer liners) | EC, CX, C, MC, M, MF, F, EF, HR |

| No of chambers | 8 |

| Weight | 29,335 kg (64,670 lb) |

| Automation (ASRi) | Optional |

| Lubrication tank | Standard |

| Offline lubrication filtration unit | Optional |

*Note: The processing capacity of the CH660 cone crusher may vary with different materials and feeding sizes.

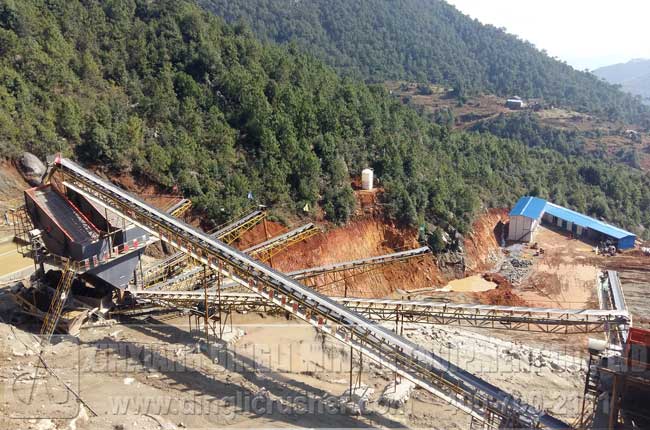

The above pictures show production site of hard rock crusher plant. Unlike traditional crushing plant it adopts only one set of hard rock crusher to complete the crushing process which greatly reduces the equipment investment and increase

As to the process of cement production you should firstly crush the materials of limestone and clay and then matching.

In this stone production line it is easy to carry out maintenance on the devices for example the hammer crusher can be opened by hydraulic pressure in order to repair and maintain the hammerhead without using external tools.

The CH660 features an advanced design with a relatively small footprint, yet it offers a high capacity considering its size. This makes it a space - efficient and productive choice for various crushing applications.

We are present worldwide and always here to help.

Get in touch today!