Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| Model | SCS200S | ||

| Cavity Type | EC | C | MC |

| Discharge opening range (mm) | 360 | 300 | 235 |

| Minimum discharge opening size (mm) | 25-54 | 22-48 | 19-48 |

| Processing Capacity (t/h) | 126-214 | 108-208 | 91-165 |

| Maximum Installed Power (kw) | 132 | ||

| Weight (excluding motor, in tons) | 12 | ||

*Note: The processing capacity of the SCS200S cone crusher may vary with different materials and feeding sizes.

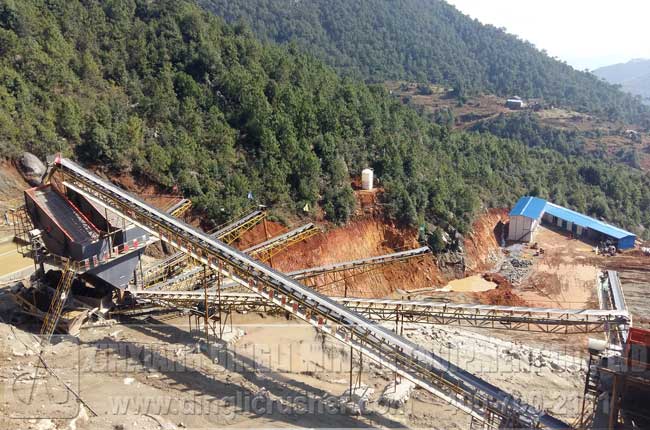

The above pictures show production site of hard rock crusher plant. Unlike traditional crushing plant it adopts only one set of hard rock crusher to complete the crushing process which greatly reduces the equipment investment and increase

The raw materials can be exploited in the place near production site which saves a lot of transport cost. All the equipment manufactured by us can right meet the requirements of the customer. With reasonable configuration such production

Xinxiang Dingli is a professional mining equipment manufacturer engaged in production of crushing and screening equipment and configuration of the gravel production lines with various capacities.

The SCS200S cone crusher is a significant player in the field of material crushing. It is designed with three distinct cavity types, namely EC, C, and MC, each offering unique advantages for different crushing applications.

The EC cavity has a discharge opening range of 360 mm, with a minimum discharge opening size varying from 25 to 54 mm. This configuration allows it to handle a wide range of materials and produce a specific output size distribution.

The C cavity, with a discharge opening range of 300 mm and a minimum discharge opening size between 22 and 48 mm, offers reliable and efficient crushing performance.

The MC cavity, featuring a discharge opening range of 235 mm and a minimum discharge opening size from 19 to 48 mm, is designed to achieve a finer crushing result.

It has a processing capacity that ranges from 126 to 214 tons per hour, making it suitable for relatively larger volume processing requirements.

Its processing capacity is 126 to 214 tons per hour, providing a consistent output for various industrial needs.

It can handle a processing capacity of 91 to 165 tons per hour, catering to applications where a more precise particle size is crucial.

Powered by a motor with a maximum installed power of 132 kw, the SCS200S is capable of driving the crushing process effectively. Despite its powerful performance, it weighs 12 tons excluding the motor, which makes it relatively easy to install and operate in different industrial settings.

Overall, the SCS200S cone crusher combines its cavity design, processing capacity, and power specifications to deliver a reliable and efficient solution for material crushing in various industries.

We are present worldwide and always here to help.

Get in touch today!