Bluestone Sand Making Production Line Process and Machine Pr

Bluestone can be used in the highway, railway, construction sand, and industrial materials making and production with different physical texture. Meanwhile, bluestone can be used in the cement and concrete material making after the sand making.

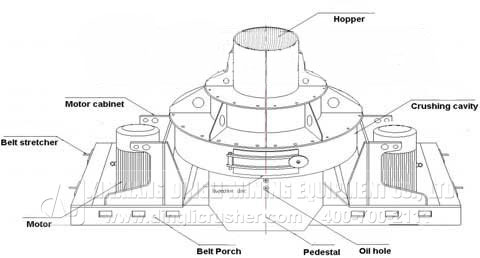

Sand maker machine working principle is mainly integrated with the crusher machine advantages and the demand of sand material size for stone material grinding. Zhongyu Dingli sand maker consisted by shell, rotor, bearing, hammerhead, vane, motor, and liner has easy machine maintenance and checking. Meanwhile, sand maker can produced materials with the demand of cubic material shape, controllable material size, and standard construction material size.

1. Sand maker working principle:

Sand making machine with the mining crusher machine advantages and connected with the actual production demand mainly works with the force of crushing and hitting. Materials in sand maker will firstly be crushed by the hitting of hammerhead and then it will be crushing again by the impact liner. After the crushing, material will fall into the bottom of sand maker for further crushing. Lastly, material will be discharged from the machine through grid for qualified material.

2. Sand maker performance advantages:

Sand maker has the feature of stable operation, safe, and environment protection, long service life, unique design, easy machine structure, cubic material size, reliable lubrication, and average finished material shape.

3. Sand maker application

a. Sand making production line process

Sand making production line has the machines of silo, vibrating feeder, crusher, sand maker, vibrating screen, and finished materials. Also there are some v-belt conveyor and chutes for machine connecting.

In production, material through the silo will be sent into the vibrating feeder, and then material will be crushed into small materials by crusher machine. After machine crushing, materials will be conveyed into the sand making machine for making sand. Then materials will be screened by the vibrating screen for the qualified material size. The unqualified material will be send into sand maker for repeated crushing.

b. Sand making production line feature

Sand making machine has the stable machine performance feature, higher production capacity, higher production automation and lower machine operation cost, higher crushing efficiency, larger production capacity, lower environmental pollution, easy machine maintenance, average material size, and reasonable material gradation.

c. Sand making production line case

4. Sand making production line and machine price

Zhongyu Dingli mining company can produce sand maker, crusher, and other mining machines after several years’ researching and getting the praise of mining machine operator. Dingli with the ideal of customer going first and credibility has the professional technicians for machine installation guidance and production line configuration. Contact our online service for machine price and production line construction.

More

- What are Stone Production Line Machines and Price?

- Method to Reduce Waste Material Rates in Stone Crushing

- Method to Reduce Waste Material Rates in Stone Crushing

- Elements of Stone Plant for Influencing Its Profits

- Cost of Configuring a Small Stone Production Line

- Stone Production Line Photograph

- Stone Production Line Photograph

NextContent:none