Stone Shaping Crusher in Secondary Crush for Better Material

Stone shaping machine is always used in the gravel and other huge production line for higher production capacity and qualified materials. Dingli is committed in producing mining crushing machines for many years. Now we have abundant types and skills in manufacturing all sorts of crushing machines of primary and secondary process.

Crusher Machine Description

Heavy hammer crusher is a widely produced and applied machine, and operated with hammer impact principle. It can be divided into primary and secondary heavy hammer crusher with production process. Primary crusher is applied to crush the aggregates of over 350Mpa compressive strength, secondary crusher is used for the material with less than 200Mpa compressive strength and over 40% calcium content, and fine crusher is generally for powder grinding and sand making.

Primary crushing: heavy hammer crusher, jaw crusher, box crusher, impact crusher, cone crusher, gyratory crusher, and ring hammer crusher.

Secondary crushing: hammer crusher, vertical shaft impact crusher, and component crusher.

Tertiary crusher: ZSJ double sand making machine, roller crusher, dual-roller crusher, ball mill, disc mill and milling machine.

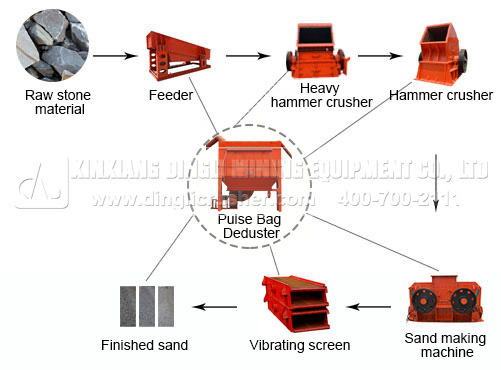

Stone Production Line Process Flow

Rock quarries are the normal home of rock crushers. Material up to about 800mm blasted from the ground is reduced in size to the correct specification for final use. Aggregates for concrete are usually crushed to 20-0mm. A conventional quarry process may consist of at least three crushing stages, a minimum installation beginning with a primary (heavy hammer) crusher to reduce all the material to less than 150-200mm. A secondary (shaping hammer) crusher is used to crush this down to around 40mm, and finally a tertiary (VSI) sand maker can shape and grade the final product ready for use in concrete or asphalt.

Shaping Crushing Machine Maintenance

Welding Alloys product specialists have developed unique techniques for protecting crushers against abrasion and impact work along their clients in order to get the best results Toper can supply turnkey constructions or wear plates for construction of crusher housing to protect surfaces against severe conditions. Benefits increase the lifetime of many different types of crushers used in the primary and secondary crushing processes. Decrease cost of maintenance in these processing areas.

E-mail dingli@dinglicrusher.com and telephone number of 0086-0373-400-700-2111 can be contacted for more information about crusher machine features and quotation.

More

- Main Stone Machine Type

- Comparison of Hammer Shaping Crusher and Impact Shaping Crus

- Stone Shaping Crusher Quotation Shaping Machine Picture

- Sand Shaping Crushing Machine Quotation and Design

- Professional Stone Shaping Crusher Manufacturer, Quotation,

- Stone Shaping Crushing Machine Type and Importance in Plant

- Shaping Crusher Price Shaping Crusher Manufacturer

NextContent:none