Features of Quality Vibration Screen

Most users will concern the price of vibration screen before purchase. But it is not quite wise to put it on the top priority. Since as important gravel production equipment for classifying the material, the vibration equipment directly affects the economic interest of customers. In the following, we would like to introduce the features of quality vibration screen.

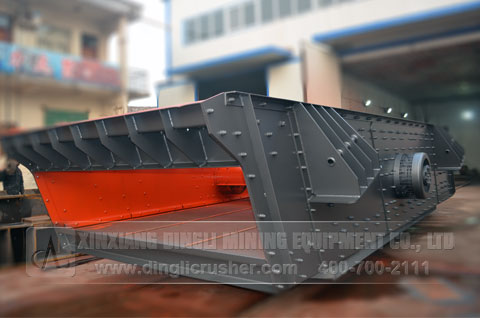

Durable Parts, Steady Operation

Gravel vibrating screen is mainly applied to process bulk material through exciting force. It requires the wear parts with strong durability so as to suffer high-intensity operation condition. The screen frame is mainly composed of side plate and cross beam. The screen frame is made from A5 or No. 20 steel plate with the depth of 6-16mm while the cross beam is made from round steel, channel steel, square pipe or beam. The shame should be solid enough so as to suffer the impact of bulk material, besides; the sieve should be wear-resistant. The molded rubber strip is required to be fixed in the bracket of screen surface by the bolts so as to reduce noise & failure and ensure steady vibration during operation.

Sound Screening Effect

In order to increase screening efficiency and achieve sound classifying effect, the material should be with required humidity and size. The screening effect is also influenced by the size of mesh size, shape and installation angle. The most influential factor is material trajectory on the screen surface. In circular trajectory, the material on the surface is loose with the bulk on the top and the small particle in lower deck. In the case of clogging, the unique sieve movement can make it jump out so as to improve the screening efficiency.

Large Capacity

The vibration screen is mainly applied in mining, metallurgy, coal and other industries for gravel screening. Against the backdrop of national policy to build large-scale gravel enterprises, the mining screen equipment with large capacity is more preferred. Therefore, it is necessary to improve and upgrade the machine size and structure while maintaining its sound performance and quality. The screener with top quality is generally featured with wide screen surface and strong exciting force.

Environmental Protection

Among the gravel production equipment, vibration screen produces most dust and noise. In the open production site, there is a lot of flying dust in the sieve and bolts connections. In order to protect environment, the vibrating screen should be added with dust cover so as to prevent powder from air. Besides, the bearing and side steel plate with good quality should be selected to reduce vibration; the rubber and plastic elements are adopted to reduce noise.

More

- Introduction of Eco-friendly Vibrating Screen

- Maintenance Tips for Quarry Vibrating Screen

- Solution of Derailing V-belt of Circular Vibrating Screen

- High Efficient Production Vibrating Screen

- Circular Vibrating Screen Parts Introduction

- Introduction of Eco-friendly Vibrating Screen

- Safe Operation Rules of Vibrating Screen

NextContent:none