Machines in Gravel Aggregates Production Line Construction

With the gravel aggregate, many people will think about the application field of construction, irrigation, and metallurgy. The popular application of gravel aggregates improves the using field and rates of mining production machines. The mining machines of crusher machine, material conveying machine, and screen machines become more popular.

The development of construction industry attract many attentions from investors, they want to put their money into mining construction. However, the first thing we should consider in selecting mining machines is machine knowledge.

Gravel aggregates production machines

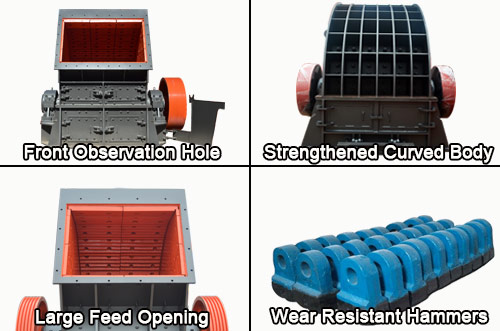

1. Crushing machines: crushing machine is an indispensable part in gravel production. And with increasing demand on gravel, it is the inevitable condition of crusher and sand maker increasing. These will hugely improve cement and concrete market. The crushing machines are hammer crusher, jaw crusher, impact crusher, and sand maker.

Hammer crusher: hammer crusher can crush huge material of 600-1800mm into no more than 25mm. It is widely used in cement, chemical, metallurgy, and so on. Zhongyu Dingli is a professional crushing machine manufacturing company with many-year manufacturing experience.

Jaw crusher machine: jaw crusher can be used in crushing bulk stone with medium hardness in mining, building material, road, railway, and chemical industry. It is available in crushing materials less than 320Mpa of coal gangue and so on.

Impact crusher machine: impact crusher machine in building material, chemical, and coal industries can be used for coarse, medium, and fine crushing medium hardness material of limestone, shale, coal, and else. Impact crusher had larger crushing ratio, easy structure, and convenient maintenance.

2. Sand making machine: sand making machine is mainly used for crushing gravel materials into quality materials for railway, building, and other constructions.

3. Feeding machine: vibrating feeder with the working way of mechanical and electrical vibration can be adjusted with machine exciting force and angle. Vibrating feeder has simple structure, convenient operation, easy maintenance, low energy consumption, adjustable material feeding.

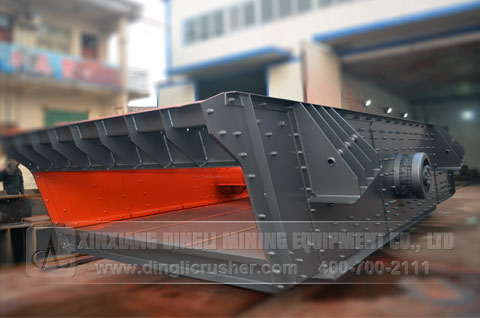

4. Screening machine: there are many types of vibrating screens of mining vibrating screen, lining vibrating screen, and efficient vibrating screen. Vibrating screen is mainly used in screening and gradation. With the structure of screen box, screen sieve, vibration device, damping spring, and structure, vibrating screen can be used for grading the crushed materials.

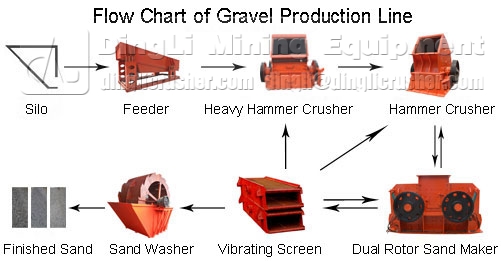

Gravel aggregates production line process

Mined limestone will be fed into heavy hammer crusher for coarse crushing by vibrating feeder. Crushed limestone will have a secondary crushing by shaping hammer crusher after conveyed by belt conveyor. And then large limestone will return into shaping crusher for repeated crushing and other materials will have sand making and washing process for demanded material quality and size.

Gravel aggregates production line performance feature:

Huge gravel aggregates production line had the feature of short process, less investment cost, low energy consumption, and wear-resistance. The finished material they produced has cubic material shape, higher hardness and strength. Also the efficient dust collector machines with over 95% dust collecting rates can hugely reduce the pollution to environment.

More

- Construction Aggregates Material Size Description

- Gravel Production Line Price

- Design Highlights of Mining Production Line

- Gravel Aggregates Line Equipment and Technique Process

- 1000TPH Gravel Production Line Machines

- About Integrated Aggregates Production Line

- What Machines are Required for Aggregate Plant?

NextContent:none