As the main ingredient of concert, aggregates are the support and skeleton of building. Xinxiang Dingli is a professor in configuring all kids of gravel production line with excellent equipment performance, high efficiency and automation.

Capacity: 50-2500t/h

Material: limestone, coal gangue, bluestone, and so on.

Aggregates are applied as skeleton and support in the buildings and important raw material for concrete preparation.

Coarse aggregates refer to the stone with the particle size larger than 4.75mm such as pebbles and crushed stone. Its raw material includes limestone, bluestone, pebbles, granite and basalt for various applications.

Fine aggregates refers to the sand with the particle size less than 4.75mm. It mainly includes natural sand like river sand, lake sand, mountain sand and sea sand through desalination and various crushed sand

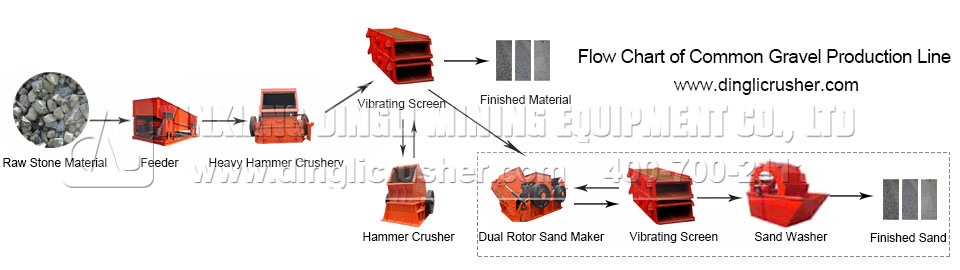

The work flow successively includes feeding, crushing and screening independently conducted by the feeder, crusher and vibrating screen. With over 30-year experience in mining industry, Xinxiang Dingli is expert in configuring the production line with the daily capacity varying from 500 ton to 30000 ton. Featured by reasonable design, little maintenance cost and durable equipment, they are warmly welcomed in the mining industry.

Vibrating feeder or other feeding equipment is applied to feed the raw material in the first process of production line.

Crushing process is the most important part for the whole production line. It adopts one or more crushers to crush various raw materials into finished material with required size.

In the production line, the crushed sand and stone material should be separated, therefore after being processed by the vibrating screen, they will be conveyed to separate silos.

The aggregates production lines are configured based on the actual conditions of local terrain.

With vigorous development of China’s real estate and building industry, it will bring a bright prospect for large eco-friendly gravel enterprises. Since 2015, many new investment modes have occurred, for example, some enterprises raise fund through issuing stocks, bonds and borrowing from banks. Moreover, more and more famous financial institutions start to input capital to the gravel and mining industry. Such changes will definitely stimulate the development of corresponding industry.

Meanwhile, the merge of gravel enterprises occurs more frequently. For example, a gravel aggregate enterprise in North China has ever acquired a private gravel plant by integrating three production lines into two with annual capacity respectively over 3 million ton.

It is an evitable trend for the large, eco-friendly and energy-saving production lines will gradually replace the small illegal ones in the near future.

Starting from a gravel production enterprise over 30 years ago, Xinxiang Dingli now is dedicated to manufacturing mining equipment and configuring various aggregates production lines. In recent years, we also set up several companies especially for producing eco-friendly and intelligent mining equipment in order to respond national call to construct green and energy-saving gravel production lines.

Dingli offers one-stop service for the customer to construct large green aggregates production line including design, manufacturing, and installation, commissioning and after-sale service. The eco-friendly fine gravel production line constructed for China United Cement Corporation in Anyang is a model in North China with annual capacity over ten million ton. We have also built many green production lines with the most advanced design and equipment for the customers across China. Welcome to visit the production sites at any time.

limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour 800TPH Crushing Production Line of Shuangsan Cement Plant

800TPH Crushing Production Line of Shuangsan Cement Plant 600TPH Aggregates Production Line in Quyang Hebei

600TPH Aggregates Production Line in Quyang Hebei 600-800TPH Production Line for Railway Construction

600-800TPH Production Line for Railway Construction 200TPH Aggregates Production Line in Tengchong Yunnan

200TPH Aggregates Production Line in Tengchong Yunnan 500TPH Stone Production Line in Jingmen

500TPH Stone Production Line in Jingmen 800TPH Stone Production Line in Hunan

800TPH Stone Production Line in Hunan 500TPH Stone Production Line in Hunan

500TPH Stone Production Line in Hunan