Gravel Aggregates Production Process

Gravel aggregates are absolutely indispensable in the process of urbanization. People who are unfamiliar with the gravel industry may be wondering how these seemingly ordinary rock particles can be obtained. This article will help you to understand the whole processes including raw material extraction and crushing & screening, etc.

First, raw material extraction

1.Water mining

As for the natural sand stone in the riverbed or riverbank, it generally adopts bucket boat for exploitation, and then the supporting sand barge is utilized for water transport to the shore, and finally transported by land vehicle to the aggregate processing site.

2. Land mining

The raw materials for artificial aggregate are usually exploited in the mountains through blasting. Blasting methods can adopt blast holes or deep-hole blasting. The blasted stone are loaded into dumper cars, trains or belt conveyors with a shovel, backhoe or loader for transporting to the processing site.

Second, processing of raw material

Natural sand and gravel recovered from water can be used directly in the construction industry by simple cleaning and grading by sand washer and screening machine. The large rocks need to be crushed and sieved before application for mixing concrete.

(A) Crushing process

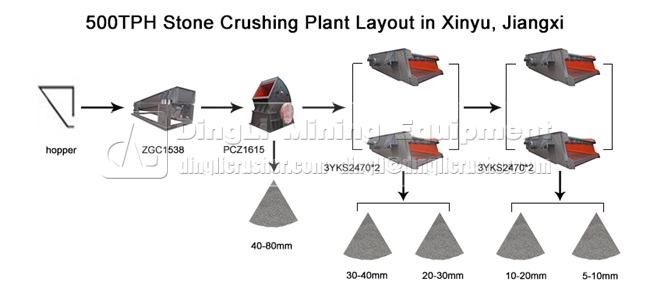

Large rocks are first discharged from the truck into the raw material warehouse, and then are fed by the vibrating feeder to the crusher in a continuous and uniform manner. The aggregate crushing process is can be divided into three stages: primary crushing (crushing the raw material to 300-70mm), secondary crushing (70-20mm) and tertiary crushing (20-1mm). Common types of rock crusher include jaw crusher, hammer crusher, impact crusher and cone crusher; the customer should refer to the material hardness, compressive strength and moisture content for right selection.

(B) Screening process

The crushed stone is transported to the vibrating screen through the belt conveyor for screening. The materials which meet customer requirements for final products are conveyed to the storage area or for next-stage processing while the unqualified materials are returned to the crusher for repeated processing.

(C) Sand making process

Through crushing and screening process, the materials that meet the size requirements of sand maker are conveyed into the machine chamber for making sand. In order to improve the cleanliness and quality of the finished aggregate, sand washing equipment needs to be configured at the end. Currently bucket wheel and spiral sand washing machines are two main types.

Through the above introduction for gravel aggregates production, we can learn each stage requires appropriate mechanical equipment. There is an old saying in China that “A handy tool makes a handy man”, which indicates it is necessary use qualified equipment manufactured by reliable factory for production of high-quality gravel aggregates.

More

- Construction Aggregates Material Size Description

- Gravel Production Line Price

- Design Highlights of Mining Production Line

- Gravel Aggregates Line Equipment and Technique Process

- 1000TPH Gravel Production Line Machines

- About Integrated Aggregates Production Line

- What Machines are Required for Aggregate Plant?

NextContent:none