Stone Powder Control & Utilization in Production Line

Release Date:2016-12-01 Click times:142 Edited by:admin

Abstract:In the operation of aggregates production line, much stone powder will be produced resulting from extra grinding. In the following, we would introduce how to control and utilize the stone powder in the production line. The fineness and grai

In the operation of aggregates production line, much stone powder will be produced resulting from extra grinding. In the following, we would introduce how to control and utilize the stone powder in the production line.

The fineness and grain size of finished material should be controlled within the limit so as to avoid extra stone powder.

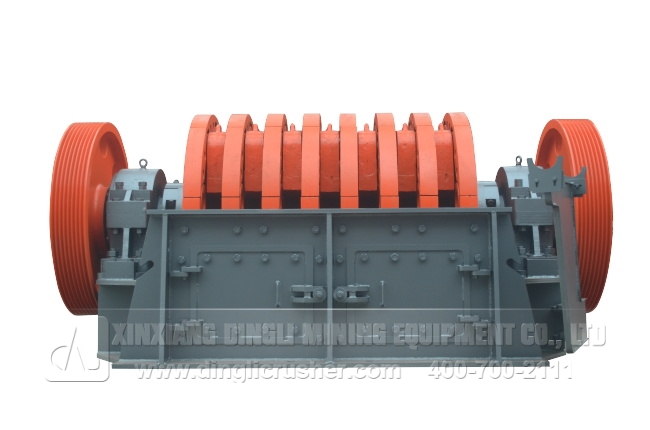

It is suggested to select the crushing equipment with the operation principle of stone hitting stone since it can prevent the material from being adhered to the crushing cavity. The crusher should also be chosen according to the hardness of crushing material.

Stone Crushing Equipment Producing Adjustable Material

The finished sand with fine grain size is directly conveyed into the silo so as to prevent stone powder from flying in the air. The deduster can be applied to fully collect the stone powder mixed in the dust for further use.

The stone powder can be utilized for cement or concrete preparation by mixing with other raw material without causing waste of resource. Currently this method has been widely applied in many areas.

More

- Construction Aggregates Material Size Description

- Gravel Production Line Price

- Design Highlights of Mining Production Line

- Gravel Aggregates Line Equipment and Technique Process

- 1000TPH Gravel Production Line Machines

- About Integrated Aggregates Production Line

- What Machines are Required for Aggregate Plant?

PreviousContent:none

NextContent:none

NextContent:none