Dingli Attended China International Aggregate Conference

From December 9 to December 10, 2017, the Fourth China International Aggregate Conference was held in Xuzhou on the theme of "Environmental Protection, Intelligent Production, Integration, Sharing, Green Waters & Mountains, Belt and Road". The event welcomed a total of more than 700 representatives including domestic government officials, scholars experts, enterprise representatives and international delegates from Britain, South Africa, Spain, Singapore, India and some countries along the Belt and Road.

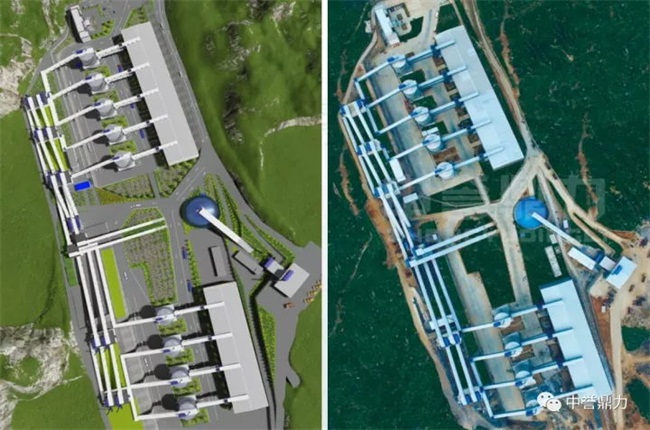

Mr. Zhang Zhimin and Mr. Yuan Wenqiu are invited to attend the meeting respectively as Chairman and General Manager of Henan Zhongyu Dingli Intelligent Equipment Co., Ltd. Mr. Zhang delivered a keynote speech on "Construction of Eco-friendly and Intelligent Production Line”. Taking the company's newly-built 3000TPH gravel aggregate production line as an example, he shared technical innovation, put forward the solutions for backward technology of traditional production line and exchange ideas with industry experts and scholars. The specific introduction for mentioned eco-friendly, innovative and intelligent aggregate crushing plant is detailed as below:

Eco-friendly & Innovative Meatures for the Stone Crusher Plant

The hopper is big enough so that 4 trucks with capacity over 60 ton can unload the raw materials at the same time. The dust collection is installed on the silo so as to collect and recycle the dust.

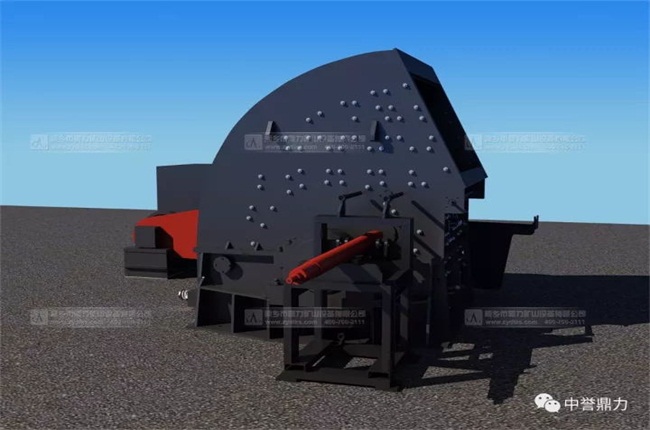

Such crusher plant is configured with a complete set of energy-efficient equipment, including vibrating feeder, primary crusher, shaping crusher and light vibrating screen, DMCA pulse bag filter and belt conveyor, etc. It is worth mentioning that PCZ2125 as primary crushing equipment has hourly capacity of 3000 ton. The whole layout is space-saving and reasonable.

The transfer storage bin is built for homogenization of crushed materials. Some are screened as finished materials and others are conveyed by the belt conveyor to the shaping machine for further processing. Moreover, it effectively separates the primary crushing process and the screening process so that the failure of each part will not affect the whole production at full capacity.

A total of nine storage tanks are set up in the stone crusher plant. Each has the capacity up to 7,000 ton and is equipped with automatic loading system; the vehicle separator is installed to prevent cheat and control the loading speed; level detector is also installed in the storage tank for real-time monitoring. The loading system and hoist consumes low power during the work; besides, the generator set is also configured to generate electricity in the event of a high-voltage power outage.

Intelligent Facilities for the Stone Crusher Plant

Facilities for achieving intelligence of the crusher plant: a central control room, two sets of management systems, five power distribution rooms, 110 units of current transducer, 36 units of vibration sensor, 63 units of speed encoding, 96 cameras, 7 automatic lubrication stations, 51 pulse control stations, and 10 units of radar level gauges.

Through cooperation of above facilities, the operators will carry out real-time and remote monitoring for the current voltage value, vibrating screen amplitude and frequency, conveyor speed and operation of production line; automatic filling of lubricants for major equipment and automatic pulse setting of dust collector.

Two industrial computers in the computing center are backed up each other. The failure of one computer will not affect the normal operation of the system. Various types of signals and data are managed by the server in a unified manner, and eventually displayed in the control room, to achieve human-computer interaction and one-button management.

The computers in control room or mobile phone of the manager will have real-time display of all kinds of data information, such as raw materials of current shift, sales of finished materials, power consumption, inventory and other information. The server can also carry out self-learning based on the previous big data and propose reasonable recommendations for the next-shift production.

The Control System of Zhongyu Dingli adopts a large number of sensors, like nerve endings, to dig out various types of data in the production line. After being successfully applied in more than ten projects, such control system can make various instructions & judgements most suitable for the stone production line. Supported by the big data analytics and deep learning algorithms, the stone crusher plant is truly intelligent and automatic.

To conclude, the innovative and automatic technologies mentioned above have also been applied in other ten large stone crusher plants across China. We will continue to make improvement and extend their applications so as to offer a best solution for the customers who plant to build the stone crusher plant.

More

- World Review on Mining Trend and Prospect

- Dingli Continues to Improve QC System with Craftsmanship

- World Review on Mining Trend and Prospect

- Yaobai Cement Ordered 4 Crushing & Screening Plants

- Sand Production Line Tends to be More Automatic

下一篇:无