How to Select Equipment Required by Gravel Plant

Most people agree that setting up a gravel plant will bring considerable profit; however, it may not be that easy without selecting suitable gravel equipment.

Early preparation: 1. Obtain a series of permits to explore the mining. 2. Purchase a complete set of equipment for gravel production line. 3. Learn operation method and strategy of the crushing line.

In the following, we will introduce the main equipment applied in gravel production lines and their respective role.

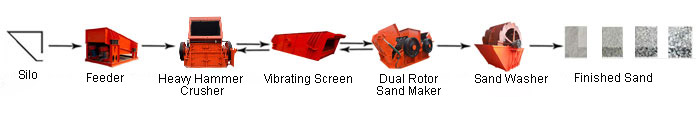

Silo-->vibrating feeder-->primary crusher-->vibrating screen-->secondary crusher-->sand making machine-->sand washer (the number of crushing equipment is determined by raw material size and requirements for finished materials, belt conveyor is used to connect gravel equipment.)

Silo stores raw material for crushing.

Vibrating feeder is for uniformly feeding material into stone crusher. It can also be applied for coarse screening.

Primary crusher crushes bulk materials.

Vibration sieve classifies crushed materials.

Secondary crusher is for repeated crushing of unqualified materials.

Sand making machine further processes stone into sand.

Sand washing machine cleans finished materials.

Belt conveyor connects two units of equipment respectively in upper and lower position and conveys the processed material into next stage.

To purchase a suitable set of gravel production equipment, we should comprehensively consider their raw material, design, performance and capacity. As a professional manufacturer of stone crushers, we always welcome your inquiry.

More

- Mining Process and Advantages of Outdoor Quarry

- Quarry Machine Quarry Production Machine Quarry Technology

- Stone Plant Machines and Price

- Common Types of Machine in the Quarry Plant

- Stone Crushing Production Line_Price_Enterprises

- Quarry Machine Types

- Stone Breaker and Company

NextContent:None