Methods to Reduce Sand Washing Cost

Release Date:2016-12-20 Edited by:admin

Sand washing machine is adopted in the production line to clear away the impurities included in the finished sand. In order to reduce the cost for sand washing, we can take several measures as advised below: Limit the feeding size below 10m

Sand washing machine is adopted in the production line to clear away the impurities included in the finished sand. In order to reduce the cost for sand washing, we can take several measures as advised below:

Limit the feeding size below 10mm and feed the material at a reasonable speed according to the capacity of sand washer so as to avoid abrasion against the equipment out of material clogging.

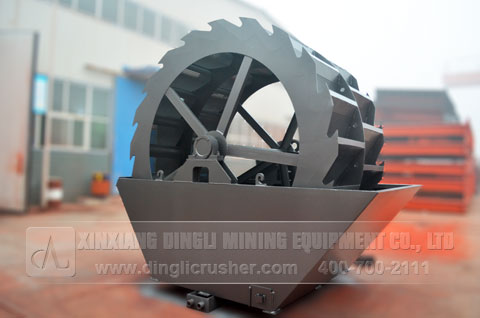

Sand Washing Machine

Reduce the amount of water utilized by the sand washing equipment. Bucket wheel sand washer generally uses recycled water to clean finished sand. A sand washing tank is specially set up below the equipment so that the water can be recycled and used for a long time.

It is advised to select the sand washing machine with wide application, which can be further used after its adoption in one production line. The bucket wheel sand washer manufactured by Dingli can be applied to both limestone and cobble, so it is widely welcomed by the customers.

With durable quality wear parts, our sand washing machine requires little maintenance and low production cost.

More

- [Buying Information] Sand Washer with Production Capacity of

- Sand Washing Machine Manufacturer, Price, Maintenance

- How to Use Sand Washer in Mining Production Line and Price

- New Energy Saving Sand Washer Working Principle and Feature

- Bucket Wheel Sand Washer Design for Better Production

- Sand Washer Machine Maintenance for Long Service Life

- Dual Rotor Sand Cleaning Machine Operation Principle

PreviousContent:None

NextContent:None

NextContent:None