Introduction of Crushing Production Line Configuration

Release Date:2017-02-08 Click times:132 Edited by:admin

Abstract:Stone production line quality is determined by its machine configuration. Many managers of stone plant have no idea of production line configuration.

Stone production line quality is determined by its machine configuration. Many managers of stone plant have no idea of production line configuration. While in purchasing Xinxiang Dingli machines, you needn’t worry these problems that we have professional technicians to design production line configuration plan.

Reasonable crushing production line configuration has high efficiency. Today we will mainly introduce you the reasonable production line configuration.

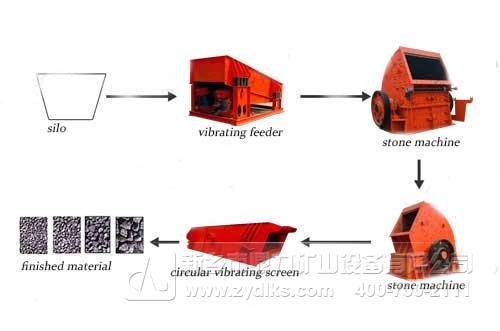

Common stone crushing production line process is silo, vibrating feeder, crusher (hammer crusher, jaw crusher, impact crusher), material return, material transit, vibrating screen, finished material. In practical configuration, production line scale, material feature, feeding and discharging material size, discharging method and special demand is needed.

1. Production scale

Each production line has output demand of 1000, 2000, or 3000ton per hour that will decide production line scale. The scale of production line is related to the type and investment costs of the whole production line. Therefore we should know the scale of production line before configuration.

2. Material features

There are many types of material of different hardness. Such as the high hardness materials of granite, basalt, cobble can be crushed by jaw crusher; medium hardness and soft materials of limestone, bluestone can be crushed by hammer crusher.

3. Feeding and discharging size

a. Feeding size is the element in choosing hammer crusher. Such as ≤500mm material can use PC-0808 hammer crusher and ≤600mm material can use PC-0910 hammer crusher;

b. Different discharging sizes determine machine production capacity.

4. Production material types

a. Two-level vibrating screen produces two finished materials and one return material.

b. Three-level vibrating screen produces three finished materials and one return material.

c. Four-level vibrating screen produces four finished materials and one return material.

5. Alternative configuration

In crushing production configuration, it is determines with actual demand. Such as, you can install a dust collector for green production or a sand washer for high quality finished material.

Zhongyu Dingli as a professional huge and medium mining machine production enterprise has expert technology groups that can design production technology and reasonable machine with different material types and finished materials demand.

More

- Precautions for Configuration of Stone Crushing Line

- Introduction of Crushing Production Line Configuration

- Quartz Sand Production Process and Machine Buying Point

- Precautions for Configuration of Stone Crushing Line

- Quick and Easy Crusher Supply of Dingli

- Cost of Configuring a Small Stone Production Line

- Road Stone Material Production Line for Construction

PreviousContent:none

NextContent:none

NextContent:none