Concrete Jaw Crusher Concrete Jaw Crusher Manufacturing

Jaw crusher is the earlier crushing machine with simple structure, strong condition, reliable operation, easy maintenance, and lower cost. Thus, jaw crusher is widely used in coarse, medium, and fine crushing ore and rocks within 147-245Mpa in mining, chemical, building material, and transportation industry.

Jaw Crushing is a technology to demolish concrete structures where we see congestion of place, less vibrations as compared to breakers, more production per day, approved technology across the globe, completely safe as less flying falling debris, economical technology also known as shear Combi- Cutters.

Being a demolition contractors company for Jaw Crushing in India we see a high demand for this technology in India in the near future and shall remain as one of the best technologies to demolish structure for years.

We as contractors master this technology as we have the best in class crushers from the world and they are sturdy and maintenance free hence we have fewer breaks down while executing contracts. This technology also has steel cutters also known as shear cutters for demolition of structural steel sheds, thin plates etc.

It is almost vibration free and does not damage the adjoining structure in case any. Concrete crushing and steel cutting is a simultaneous activity.

More information as follows:

1. Structures

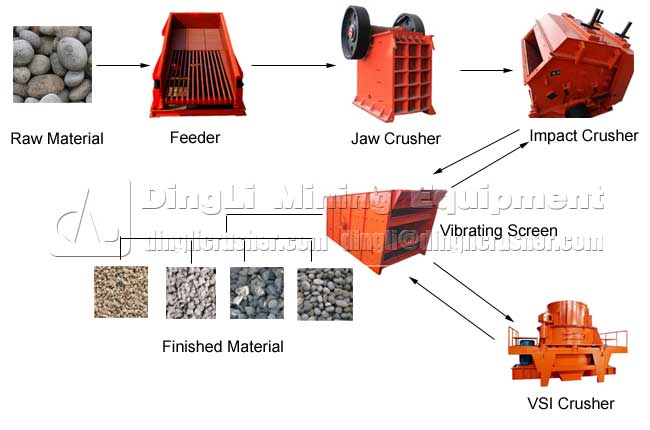

Concrete jaw crusher is composed of bracket, jaw, eccentric shaft, jaw plate, spring, etc.

2. Application

Feeding size: 120-1500mm

Production capacity: 50-2200t/h

Material: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, rocks, ore, glass, cement clinker and some metal.

Application field: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

3. Concrete jaw crusher Features:

a. Deep crushing cavity without dead zone.

b. The gasket type adjusting device of the discharge gate is characterized by reliable performance, convenient use, large adjusting range, and improves the equipment flexibility.

c. The lubricating system of jaw crusher is safe and reliable.

d. A single machine saves 15%~30% of energy consumed and the system can save over half the energy consumed.

e. This machine causes low noise and creates little dust.

Dingli is the only enterprise which has own stone crushing line in the industry. All the new equipment will be firstly applied in the plant for trial before its launch into the market. Learn more with our online service or send message to dingli@dinglicrusher.com.

NextContent:none