When do We Change Jaw Crusher Wear Parts

It is known that jaw crusher is the most common crusher machines in mining industry production. As to machine checking and maintenance, users always with the view that we can change machine after failure. But it would effectively protect machine with timely and regular checking and changing.

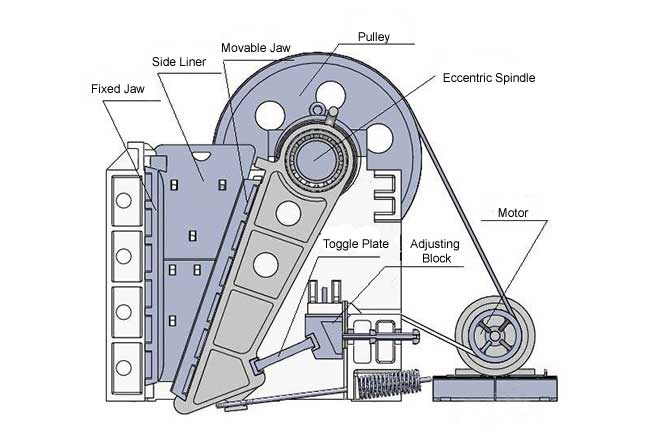

Change machine according to its wear condition. Fixed liner, movable jaw liner, and side liners of jaw crusher are the important and easy-wear parts in production process.

At the beginning of machine using, pinion rack have a turn using. As to jaw plate, they always be abraded in middle and lower place, so change a new plate when there are 3/5 pinion rack wear or 2/5 side liner wear. Spindle with less wear can be reused with turnery and inner size reducing; otherwise, you should change a new one.

These problems are the easy wear places that you should have a regular check and timely change.

Jaw crusher spare parts should be change timely in case of reducing machine efficiency or even breaking machine.

Jaw crusher Babbit lining can have about two-year life span under impacting operation, which should be recasting for continue using. The gap between eccentric spindle and bearing bush should not more than 1.5 times of the original one. Oil groove should have be adjusted or remade with over 1.5mm wear. Adjust or change parts with 1.5 times wear than assembling gap. Recasting Babbit of bearing bush as there is wear condition. The requirement of bearing bush is average, silver white color, without lime-ash, flaw, sand hole, shrinkage cavity, and extraction.

NextContent:none