Recycled Concrete Application and Concrete Crusher

Concrete recycling has been a global trend. Concrete can be recycled and reused in many ways based on the size and shape of the concrete. Reusing concrete is a way to reduce construction costs and provide some benefits to the environment when you reuse that concrete. The concrete can be recycled and applied as follows:

1. Reclaimed concrete can be used in walkways providing a walkable surface and at the same time providing gaps for rain water to reach the soil. By doing this the amount of runoff water will also be reduced, resulting in a smaller storm sewer system.

2. Old concrete can be recycled and turn into aggregates after it has been crushed and processed.

3. Concrete pavements can be broken in place and used as a base course for an asphalt pavement through a process called rubblization.

4. Recycled concrete can be used as a bed foundation in which to lay underground utilities.

5. Recycled aggregate (crushed concrete) can be combined with virgin aggregate when used in new concrete.

6. Recycled concrete from construction has been used as a material to generate new reefs habitats.

Benefits of Concrete Recycling

As you start to recycle concrete, you will get some additional benefits such as:

1. It will reduce your construction waste and will extend the life of landfills for additional years.

2. The LEED® Green Building Rating System recognizes recycled concrete in its point system and you will earn points towards the certification.

3. Recycled concrete can substitute virgin aggregates and will reduce the environmental costs of natural resources.

4. Reduced transportation cost: concrete can often be recycled on demolition or construction sites or close to urban areas where it will be reused.

5. Reduced disposal costs as landfill taxes and tip fees can be avoided.

6. It can be used as excellent aggregates for road bases, slope protection and earth retention structures.

7. In some instances, employment opportunities arise in the recycling industry that would not otherwise exist in other sectors.

How Concrete is Recycled

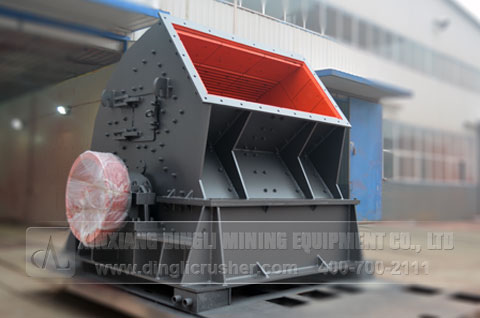

Concrete is recycled by using crushing equipment such as jaw crusher and hammer crusher. Besides, a secondary crusher and vibrating screens are also used for the recycling process. One of these screens will be used to remove dirt and particles from concrete and a second screen will be used to remove coarse aggregate. The additional methods such as water floatation, separators and magnets are used to remove additional components from the concrete. Depending on the process you are trying to establish, pulverizing concrete is not the best option as it will be harder to complete the separation process, contaminating the smaller by-products.

Equipment Used to Recycle Concrete

When considering to recycle concrete, you will also need to evaluate the options available to crush the concrete. The portable crusher may be a relatively practical solution, as it will add mobility and can be used in different locations and projects. However, we have to admit that portable crusher has its own limitations, high cost and low capacity. As for the large concrete recycling project, we recommend static hammer crusher crushing process instead, the capacity of which can be up to 3000 ton per hour.