Functions of Cement Crusher Machine in Cement Plant Growth

With the speedup of industrialization, the industry waste increases with date. In order to enforce the using and recycling of waste material, the handling of waste material attracts many attentions. The huge cement enterprise enters into the gravel aggregates industry.

Building material is one of the huge pillar industries and cement is the main elements of building material. The increasing of environmental protection makes cement industry with higher pollution problems should be upgraded. The development of cement industry should be with the trend of sustainable, stable, and healthy. And crusher machine as the important processing machine should be upgraded with trend and society demand.

The main crushing machines include heavy hammer crusher, hammer crusher, jaw crusher, cone crusher, and impact crusher machines.

Material

1. Cement material has six types of silicate cement, ordinary silicate cement, ore cement, tephra cement, coal cement, and compound cement.

2. Cement concrete is called the mix of cement, gravel, stone and water for the using of building.

Cement crusher machine

1. Working principle: hammer crusher mainly crushes material with hammerhead for medium and fine crushing. Hammerhead installs in rotor for crushing and grid is installed under the machine for controlling material size. Material is firstly crushed by hammerhead and then crushing plate. Crushed material will discharged from crusher through grid.

2. Feature: higher crushing ratio, average discharge material size, less powder, and lower energy consumption.

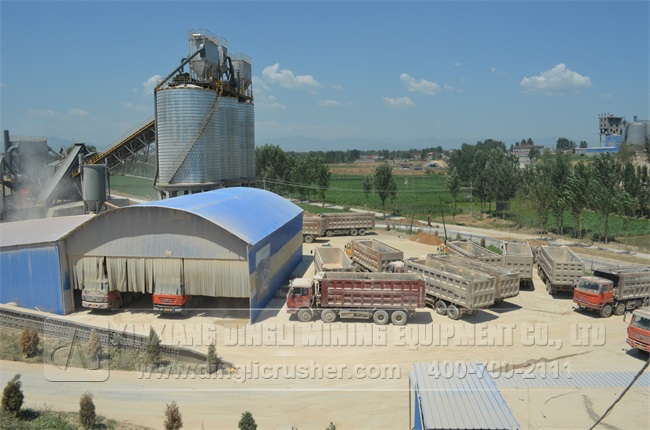

Cement crushing production line site and basic configuration

Vibrating feeder + Hammer crusher + Vibrating screen + Dust collector

Consultation

Please contact with our online service or send e-mail to dingli@dinglicrusher.com.