Automatic Lubrication System of Vibrating Screen

Release Date:2017-01-06 Edited by:admin

Lubrication technology improving can ensure normal operation, extend service life, and reduce wear condition for a better operating effect.

Friction is inevitable during the operation of each machine; less friction will extend service life of machine with regular lubrication. The concentrated and automatic lubrication system researched by Zhongyu Dingli has regular lubrication, high maintenance efficiency.

Hydraulic automatic lubrication technology avoids many disadvantages of artificial lubrication oil adding that can control adding parts but time and frequency.

With several months’ experiment of lubrication technology, Zhongyu Dingli enjoys good reputation after sale with 3-6 months automatic lubrication in vibrating screen.

Enhance lubrication technology can ensure normal operation, long service life, less wear condition. Thus we should improve lubrication technology for better operation.

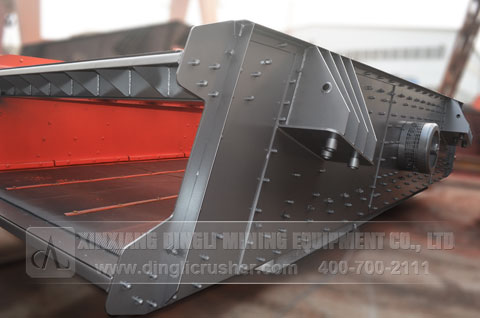

Diagram of vibrating machine

Lubricating parts of vibrating screen

Eccentric block: viscosity is important in lubrication that high eccentric speed will have lower viscosity.

Bearing parts: lubrication oil is crucial for vibrating bearing parts that will reduce service life with improper lubrication.

More

- 8 Tips to Improve Efficiency and Effect of Vibrating Screen

- Mining Vibrating Screen Type Parameter and Company

- Vibrating Screen Maintenance and Reasons of Clogging

- How to Select Suitable Vibration Screen among Mining Market?

- Four Tips for Improving Efficiency of Vibrating Screen

- Analysis on Stone Plant Vibrating Screen Maker Spare Parts

- Vibrating Feeder Application Field and Working Principle

PreviousContent:None

NextContent:None

NextContent:None