Energy Saving Character and Maintenance of Sand Maker

High efficient sand maker also called sand making machine. It is widely used in crushing high hardness materials of ores, cement, glass, building sand, stone, and other metal materials and wear and hostile materials. It is available in mining sector of producing artificial sand, concrete, and cements aggregates for grinding.

Comparison between ZSJ Dual Rotor Sand Maker and Other Machines

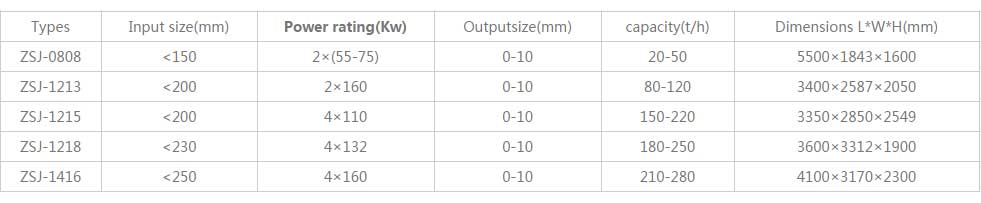

ZSJ Dual Rotor Sand Maker Parameter:

Other Types of Sand Maker

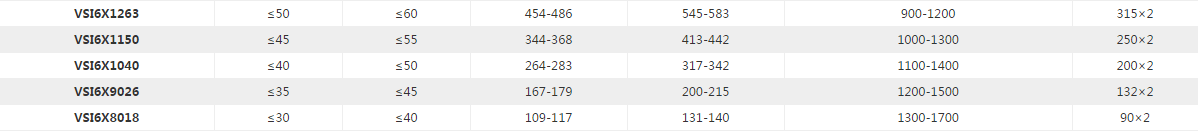

Vertical Shaft Sand Maker Parameter:

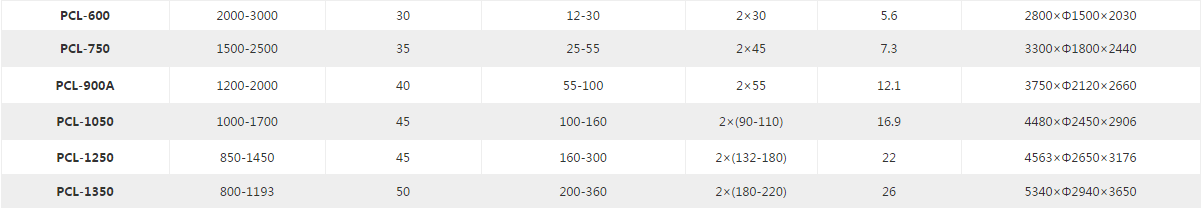

PCL Impact Sand Maker Parameter:

Upon the data above, we get to know ZSJ dual rotor sand maker has larger feeding material size that can reduce investment costs with less crushing machine. For instance, in crushing granite, dual rotor sand maker has high efficiency that only needs one crushing machine.

In the lists of electric power and output, dual rotor sand maker has small power and high output.

In maintenance:

1. Hydraulic opening device. As machine stop working, hydraulic opening can motivate machine for easy rotor, grind, and wear parts changing. Also it can improve its productivity, reduce maintainer working strength.

2. There is an observance door under the two rotors for easy maintenance or checking clogging condition that can save check and clean times and improve using rates and crushing capacity.

More

- Recommend of Sand Machine Enterprise

- Common Layout for the Stone Production Line

- Failure&Maintenance in Sand Machine Operation

- Recommend of Sand Machine Enterprise

- Dust Collector for Stone Crusher Equipment

- Method on Stone Sand Machine Maintenance

- Guilin Sand Machine Price

NextContent:none