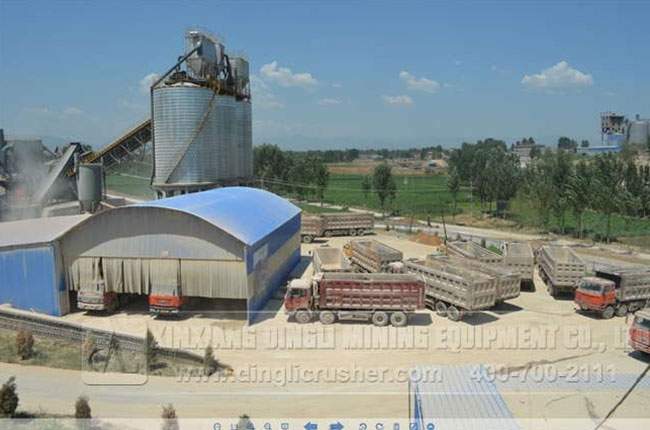

500TPH Cement Aggregates Production Line in Hebei

Project features: automatic control system, one-button power-up, automatic materials distributing, automatic loading, hourly output of 500-600 ton, closed environmental protection system, improvement of waste utilization.

Application: as a new profit growth point, the aggregates are used to produce raw materials for concrete and cement preparation.

Production line configuration: Dingli’s vibrating feeder: ZG1550 * 1 set,heavy hammer crusher PCZ1615, hammer shaping machine: PC1216, dual rotor sand maker: ZSJ1213, circular vibrating screen: 3YKZ2670 * 2 sets, 2YKZ3070 * 2 sets, 2YKZ3070 * 2 sets, deduster: LDMC64-4*4 sets, LDMC64-5*8 sets; combined sand separator: 1 set

Background: with the extension of the industry and waste utilization, the cement plant begins the exploration into the industry of stone plant. With the high-quality aggregates production line, the profit of the cement plant has been effectively increased by providing fine stone.

Analysis:

1. Process design: the 500-600T/H production line of China United Cement Corporation in Hebei adopts heavy hammer crusher PCZ1615 for primary crushing and PC1216 for secondary crushing, which effectively improves the capacity with grain shape being rounder and the flake rate being lowered. The crushed materials first go through the combined screens (two sets of 3YKZ2670) with a type of finished materials being produced and the unqualified materials being returned to the secondary crusher, then successively going through the 3YKZ3070 and 2YKZ3070 screens for screening the finished materials. The materials less than 200mm are transported to the ZSJ1216 sand maker for crushing with the finished material less than 5mm being discharged. The whole procedure needs 4 sets of LDMC64-4, 8 sets of LDMC64-5 and 1 set of combined sand separator for dedusting and sand separation. After effective dedusting and sand separation, the stone powder can be used as calcium powder and other materials. The whole process is controlled by the automatic system and installed with dedusting devices in line with national environmental requirements.

2. Production & installation: the contract was signed in December 2013. It has lasted for 8 months to complete the cement plant from the civil engineering to successful test running. The entire production line adopts China’s leading technology with automatic control system.

More

- 1000TPH Gravel Production Line in Xingyang, Henan

- 600TPH Gravel Production Line in Hangzhou, Zhejiang

- 1200TPH Gravel Production Line in Guiyang, Guizhou

- 700TPH Gravel Production Line of Mengyin Stone Plant

- 500TPH Gravel Production Line in Xinmi, Henan

下一篇:无