I. Description Basalt is a basic volcanic rock mainly consisting of silicon dioxide, alumina, iron oxide, calcium oxide, magnesium oxide (and some calcined potash and sodium oxide), among which, the silicon dioxide accounts for the most proportion of 45%-50%. Basalt is usually black, dark grey or dark green. With tight texture, the basalt has the specific gravity heavier than that of ordinary basalt, limestone, sandstone, and shale. Some basalt is called float stone since it can float on the water with reduced weight due to having many pores.

It is the main element of the earth oceanic and continental crust and lunar mare and terrain. It is mainly used as construction material of building and road, and widely applied in chemical industry, wear resistant and thermal insulation material, human defense project etc. Due to large particle size, the exploited basalt aggregates shall be crushed into the materials with small size before its application in the actual production and construction.

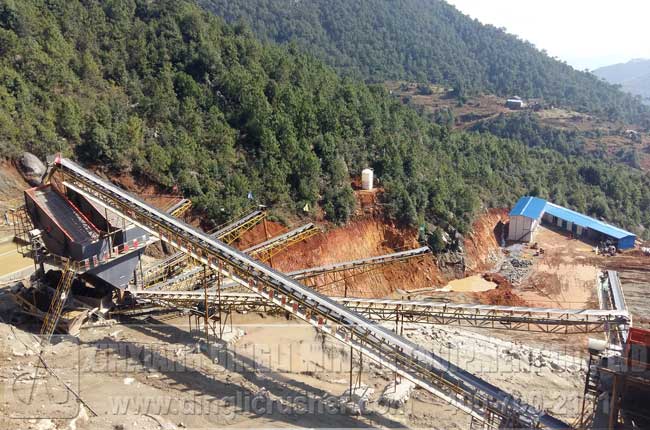

600T/H Basalt Production Line: after being blasted from the mountain, the stone less than 1020mm is sent into the vibrating feeder by dumper and then evenly fed into jaw crusher for primary crushing. With the particle size of 150mm-300mm, the stone coming out of the jaw crusher will be conveyed to the impact crusher for secondary crushing and shaping. After being screened and graded by the circular vibrating screen, the block materials with the size larger than finished material will be returned to the impact crusher for re-crushing while the finished materials are conveyed to the Finished Product Area by the belt conveyor.

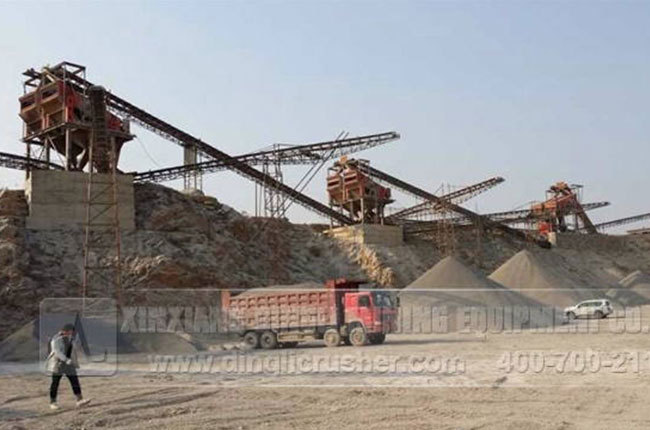

700TPH Stone Plant in Chongqing

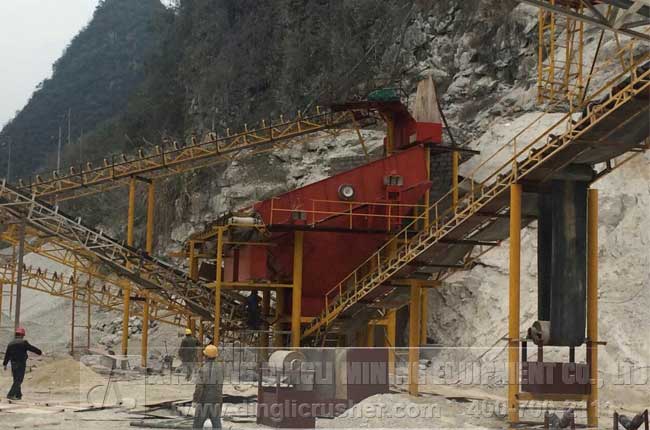

700TPH Stone Plant in Chongqing 1500TPH Limetone Production Line in Sichuan

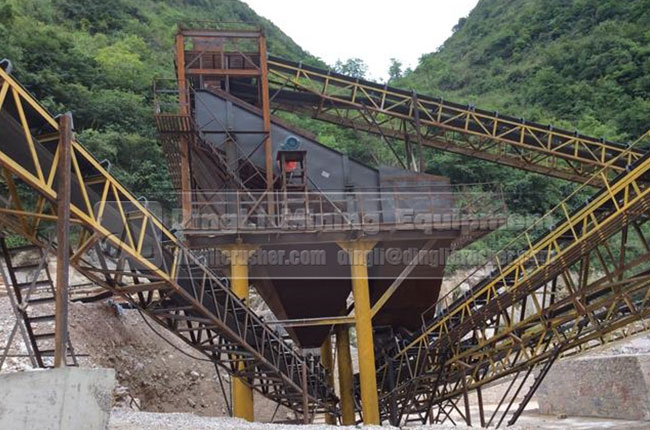

1500TPH Limetone Production Line in Sichuan 1200TPH Stone Production Line in Chuzhou Anhui

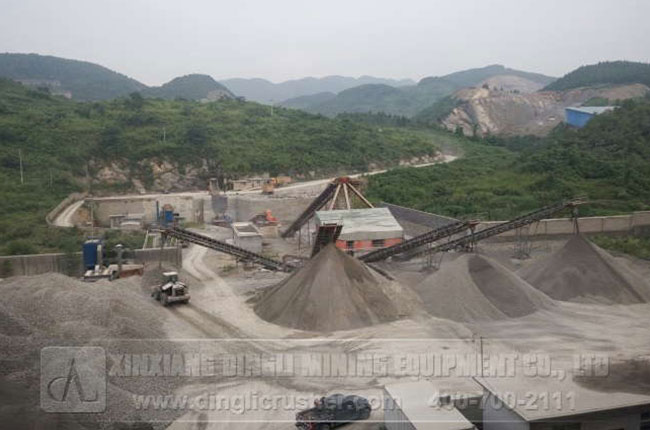

1200TPH Stone Production Line in Chuzhou Anhui 1500TPH Aggregates Production Line of China United Cement

1500TPH Aggregates Production Line of China United Cement 300TPH Stone Production Line in Guizhou

300TPH Stone Production Line in Guizhou 500TPH Sand Making Production Line in Hunan

500TPH Sand Making Production Line in Hunan Stone Production Line in Laibin Guangxi

Stone Production Line in Laibin Guangxi 800-1000TPH Limestone Crushing Line in Sichuan

800-1000TPH Limestone Crushing Line in Sichuan 500TPH Limestone Crushing & Screening Plant Solution

500TPH Limestone Crushing & Screening Plant Solution 500TPH Stone Production Line in Huangshi Hubei

500TPH Stone Production Line in Huangshi Hubei 300TPH Stone Plant in Guilin Guangxi

300TPH Stone Plant in Guilin Guangxi 600TPH Stone Production Line in Pingdingshan

600TPH Stone Production Line in Pingdingshan Songji Cement Plant in Dengfeng Henan

Songji Cement Plant in Dengfeng Henan 1200TPH Cement Aggregates Production in Xingtai Hebei

1200TPH Cement Aggregates Production in Xingtai Hebei 10000TPD Stone Crusher Plant in Xingyang Henan

10000TPD Stone Crusher Plant in Xingyang Henan 600-800TPH Gravel Crushing Plant in Tengchong Yunnan

600-800TPH Gravel Crushing Plant in Tengchong Yunnan 300TPH Stone Plant in Laibin Guangxi

300TPH Stone Plant in Laibin Guangxi 1000TPH Stone Production Line in Guizhou

1000TPH Stone Production Line in Guizhou 5000TPH Limestone Crusher Plant in Zhumadian

5000TPH Limestone Crusher Plant in Zhumadian Stone Crushing Plant in Huaibei Anhui

Stone Crushing Plant in Huaibei Anhui 50TPH Sand Production Line in Changde Hunan

50TPH Sand Production Line in Changde Hunan 800TPH Stone Production Line in Hunan

800TPH Stone Production Line in Hunan 500TPH Stone Production Line in Jingmen

500TPH Stone Production Line in Jingmen 200-250TPH Sand Making System of Zoomlion in Anyang

200-250TPH Sand Making System of Zoomlion in Anyang 250TPH Stone Production Line in Shiyan City Hubei

250TPH Stone Production Line in Shiyan City Hubei 300TPH Stone Production Line in Pingba Anshun Guizhou

300TPH Stone Production Line in Pingba Anshun Guizhou 400TPH Stone Production Line of Zhonglei Company

400TPH Stone Production Line of Zhonglei Company 500-800TPH Gravel Crushing Project of Shiyu Concrete Company

500-800TPH Gravel Crushing Project of Shiyu Concrete Company Eco-friendly Stone Plant in Tianshui Gansu

Eco-friendly Stone Plant in Tianshui Gansu Cement Plant of China United Cement Corporation in Hebei

Cement Plant of China United Cement Corporation in Hebei 1500TPH Aggregates Production Line in Huaiyuan Bengbu

1500TPH Aggregates Production Line in Huaiyuan Bengbu 500TPH Stone Production Line in Hunan

500TPH Stone Production Line in Hunan 800TPH Stone Production Line of Lizhi Stone Company

800TPH Stone Production Line of Lizhi Stone Company 500TPH Stone Plant in Taiyuan Shanxi

500TPH Stone Plant in Taiyuan Shanxi 900-1000TPH Stone Plant in Tangwan Daye Hubei

900-1000TPH Stone Plant in Tangwan Daye Hubei 1500TPH Stone Production Line in Leiming Mining Plant

1500TPH Stone Production Line in Leiming Mining Plant 300TPH River Pebble Crusher Plant in Chongqing

300TPH River Pebble Crusher Plant in Chongqing 2000TPH Stone Production Line in Guangan Sichuan

2000TPH Stone Production Line in Guangan Sichuan 200TPH Aggregates Production Line in Tengchong Yunnan

200TPH Aggregates Production Line in Tengchong Yunnan 600TPH Stone Crusher Plant in Sichuan

600TPH Stone Crusher Plant in Sichuan 600TPH Stone Production Line in Liuzhou Guangxi

600TPH Stone Production Line in Liuzhou Guangxi 1200TPH Stone Production Line in Huzhou Zhejiang

1200TPH Stone Production Line in Huzhou Zhejiang 600-800TPH Aggregates Production Line in Sanguankou

600-800TPH Aggregates Production Line in Sanguankou 800-1000TPH Gravel Crushing Line in Guangxi

800-1000TPH Gravel Crushing Line in Guangxi 300TPH Stone Production Line in Lvliang Shanxi

300TPH Stone Production Line in Lvliang Shanxi 1000TPH Stone Production Line in Yibin

1000TPH Stone Production Line in Yibin 500TPH Stone Production Line in Yichun Jiangxi

500TPH Stone Production Line in Yichun Jiangxi 250TPH Stone Crusher Plant Solution and Pics

250TPH Stone Crusher Plant Solution and Pics 700TPH Stone Crusher Plant for Guangtaihe Mining in Shanxi

700TPH Stone Crusher Plant for Guangtaihe Mining in Shanxi 1000TPH Stone Plant in Yidu Hubei

1000TPH Stone Plant in Yidu Hubei 1000TPH Stone Production Line in Yichun Jiangxi

1000TPH Stone Production Line in Yichun Jiangxi 300TPH Stone Production Line in Sichuan

300TPH Stone Production Line in Sichuan 500TPH Stone Production Line in Lanzhou Gansu

500TPH Stone Production Line in Lanzhou Gansu 6000TPD Gravel Aggregates Plant in Pingtang Guizhou

6000TPD Gravel Aggregates Plant in Pingtang Guizhou 200TPH Stone Production Line in Xinjiang

200TPH Stone Production Line in Xinjiang 500TPH Lime Processing Plant in Chongyang Xianning

500TPH Lime Processing Plant in Chongyang Xianning 1200TPH Aggregates Production Line of Shuaibao Plant

1200TPH Aggregates Production Line of Shuaibao Plant 400TPH Stone Production Line in Xianning Hubei

400TPH Stone Production Line in Xianning Hubei 700TPH Gravel Production Line of Hongyuan Group in Linhe

700TPH Gravel Production Line of Hongyuan Group in Linhe 500TPH Stone Crushing Plant in Shaoyang Hunan

500TPH Stone Crushing Plant in Shaoyang Hunan 3000TPH Aggregate Production Line for Building Materials Corp

3000TPH Aggregate Production Line for Building Materials Corp 800TPH Gravel Aggregate Production Line for Sale

800TPH Gravel Aggregate Production Line for Sale 500TPH Gravel Production Line in Liangshan Sichuan

500TPH Gravel Production Line in Liangshan Sichuan 400-500TPH Gravel Line for Railway Construction

400-500TPH Gravel Line for Railway Construction 600-800TPH Stone Production Line in Huaibei Anhui

600-800TPH Stone Production Line in Huaibei Anhui 1000TPH Stone Production Line in Xichang Liangshan

1000TPH Stone Production Line in Xichang Liangshan 350TPH Limestone Aggregate Production Line

350TPH Limestone Aggregate Production Line 700TPH Fluorite Production Line in Jiujiang

700TPH Fluorite Production Line in Jiujiang 600-700TPH Aggregates Production Plant in Sichuan

600-700TPH Aggregates Production Plant in Sichuan 800TPH Stone Production Line in Guyuan Ningxia

800TPH Stone Production Line in Guyuan Ningxia 2000TPH Gravel Aggregates Production Line in Xianning

2000TPH Gravel Aggregates Production Line in Xianning 300TPH Stone Plant in Xiangzhou Guangxi

300TPH Stone Plant in Xiangzhou Guangxi 800TPH Stone Plant in Liuzhou Guangxi

800TPH Stone Plant in Liuzhou Guangxi 2500TPH Aggregates Production Line of Henan Mengdian Cement

2500TPH Aggregates Production Line of Henan Mengdian Cement Automatic Stone Production Line in Guizhou

Automatic Stone Production Line in Guizhou 420-500TPH Stone Production Line in Yuanzhou Yichun

420-500TPH Stone Production Line in Yuanzhou Yichun 1000TPH Gravel Production Line in Mangao Huishui Guizhou

1000TPH Gravel Production Line in Mangao Huishui Guizhou Stone Crushing Plant in Hunan

Stone Crushing Plant in Hunan 1000TPH Stone Crusher Plant in Xinmi Henan

1000TPH Stone Crusher Plant in Xinmi Henan 300TPH Stone Crushing Line for Sand Production

300TPH Stone Crushing Line for Sand Production Solution for 4000TPH Limetone Crusher Plant

Solution for 4000TPH Limetone Crusher Plant 500TPH Stone Plant of Qiang Nationality in Sichuan

500TPH Stone Plant of Qiang Nationality in Sichuan 400TPH Stone Production Line in Yichang

400TPH Stone Production Line in Yichang 600TPH Stone Plant in Nanning Guangxi

600TPH Stone Plant in Nanning Guangxi 2500 Ton/Day Gravel Production Line in Yongzhou Hunan

2500 Ton/Day Gravel Production Line in Yongzhou Hunan 300TPH Stone Production Line in Lianhua Jiangxi

300TPH Stone Production Line in Lianhua Jiangxi 1200TPH Gravel Production Line of Yijian in Guiyang Guizhou

1200TPH Gravel Production Line of Yijian in Guiyang Guizhou 600TPH Aggregates Production Line in Quyang Hebei

600TPH Aggregates Production Line in Quyang Hebei 800TPH Gravel Production Line in Guangan

800TPH Gravel Production Line in Guangan 1000TPH Cement Crushing Production Line

1000TPH Cement Crushing Production Line 3500TPD Stone Crushing Project in Meishan Sichuan

3500TPD Stone Crushing Project in Meishan Sichuan 800TPH Stone Production Line in Guilin Guangxi

800TPH Stone Production Line in Guilin Guangxi 600-800TPH Stone Production Line of Lutong Company

600-800TPH Stone Production Line of Lutong Company 450TPH Stone Plant in Kunming Yunnan

450TPH Stone Plant in Kunming Yunnan 600TPH Sand Production Line in Sichuan

600TPH Sand Production Line in Sichuan Manufactured Sand Production Line in Henan

Manufactured Sand Production Line in Henan 800TPH Production Line of Guixing Cement Plant

800TPH Production Line of Guixing Cement Plant 5000TPD Gravel and Aggregate Production Line in Yichun Jian

5000TPD Gravel and Aggregate Production Line in Yichun Jian 3000TPH Aggregates Production Line of Hengqiang Mining

3000TPH Aggregates Production Line of Hengqiang Mining 800TPH Stone Production Line in Pingliang Gansu

800TPH Stone Production Line in Pingliang Gansu 500TPH Crushing Production Line for Concrete Plant

500TPH Crushing Production Line for Concrete Plant 500TPH Stone Production Line in Zunyi Guizhou

500TPH Stone Production Line in Zunyi Guizhou Hammer Crusher Application Case in Sichuan

Hammer Crusher Application Case in Sichuan 600TPH Gravel Production Line in Meishan City Sichuan

600TPH Gravel Production Line in Meishan City Sichuan Sand Production Line in Sanyuan Shaanxi

Sand Production Line in Sanyuan Shaanxi 1000TPH Stone Crusher Plant Newly Built for Ningxia Customer

1000TPH Stone Crusher Plant Newly Built for Ningxia Customer 160TPH Stone Plant in Guangxi

160TPH Stone Plant in Guangxi 800-1000TPH Aggregate Production Line for Sale

800-1000TPH Aggregate Production Line for Sale 300TPH Sand Making Production Line in Hunan

300TPH Sand Making Production Line in Hunan 10000TPD Stone Production Line in Pingshun Shanxi

10000TPD Stone Production Line in Pingshun Shanxi 1000TPH Aggregates Production Line in Zunyi Guizhou

1000TPH Aggregates Production Line in Zunyi Guizhou 1200-1500TPH Stone Production Line in Ruichang Jiujiang

1200-1500TPH Stone Production Line in Ruichang Jiujiang Stone Production Line of Leiming Mining Industry

Stone Production Line of Leiming Mining Industry 500TPH Limestone Production Line of Malan Cement Plant

500TPH Limestone Production Line of Malan Cement Plant 1500TPD Gravel Production Line in Neijiang

1500TPD Gravel Production Line in Neijiang 300TPH Stone Crusher Plant in Qixian Henan

300TPH Stone Crusher Plant in Qixian Henan 500-700TPH Production Line of Dongfang Cement Corporate

500-700TPH Production Line of Dongfang Cement Corporate 500TPH Aggregates Production Line of Longshan Cement

500TPH Aggregates Production Line of Longshan Cement 10000TPD Stone Production Line in Lvliang Shanxi

10000TPD Stone Production Line in Lvliang Shanxi 200TPH Aggregates Production Line in Ningxia

200TPH Aggregates Production Line in Ningxia Cost-effective Solution for 300TPH Sand Making Plant

Cost-effective Solution for 300TPH Sand Making Plant Aggregates Production Line of Yongshun Alumina

Aggregates Production Line of Yongshun Alumina 800-1000TPH Stone Production Line in Shanhe Yongqing

800-1000TPH Stone Production Line in Shanhe Yongqing 600TPH Stone Production Line in Zunyi Guizhou

600TPH Stone Production Line in Zunyi Guizhou Stone Production Line for Airplane Construction

Stone Production Line for Airplane Construction 300TPH Rebuild Aggregates Production Project of Saima

300TPH Rebuild Aggregates Production Project of Saima 300TPH Stone Crusher Plant in Yichang Hubei

300TPH Stone Crusher Plant in Yichang Hubei Installation Site of Taiyangshi Cement Corporate

Installation Site of Taiyangshi Cement Corporate 200TPH Stone Crushing Plant in Jiangxi

200TPH Stone Crushing Plant in Jiangxi Stone Crushing Plant of China United Cement Corporation

Stone Crushing Plant of China United Cement Corporation 250-320TPH Stone Production Line in Jiangxi

250-320TPH Stone Production Line in Jiangxi 650-800TPH Stone Production Line in Hukou

650-800TPH Stone Production Line in Hukou Stone Crusher Plant of Yuanda Mining in Hubei

Stone Crusher Plant of Yuanda Mining in Hubei Production Site of Yunnan Concrete Mixing Station

Production Site of Yunnan Concrete Mixing Station 1500TPH Crushing Production Line of Chunjiang Cement

1500TPH Crushing Production Line of Chunjiang Cement 600TPH Stone Production Line in Yuzhou Henan

600TPH Stone Production Line in Yuzhou Henan 1600TPH Bluestone Production Line in Sichuan

1600TPH Bluestone Production Line in Sichuan 800TPH Crushing Production Line of Shuangsan Cement Plant

800TPH Crushing Production Line of Shuangsan Cement Plant 800-1200TPH Cement Crushing Production Line in Guixing

800-1200TPH Cement Crushing Production Line in Guixing 800TPH Aggregates Production Line in Sanmenxia

800TPH Aggregates Production Line in Sanmenxia 500TPH Stone Production Line in Pingliang Gansu

500TPH Stone Production Line in Pingliang Gansu 1200TPH Stone Production Line in Wuxue Hubei

1200TPH Stone Production Line in Wuxue Hubei 600TPH Gravel Production Line in Guangan City

600TPH Gravel Production Line in Guangan City 600-800TPH Production Line for Railway Construction

600-800TPH Production Line for Railway Construction 200TPH Stone Plant in Baoan County Daye Hubei

200TPH Stone Plant in Baoan County Daye Hubei 300TPH Gravel Production Line for Railway Construction

300TPH Gravel Production Line for Railway Construction 1000TPH Stone Production Line of Shangtong CO. Ltd.

1000TPH Stone Production Line of Shangtong CO. Ltd. 300TPH Stone Plant in Leqing Zhejiang

300TPH Stone Plant in Leqing Zhejiang Stone Production Line in Chenxia Industrial of Zhengzhou

Stone Production Line in Chenxia Industrial of Zhengzhou 700TPH Stone Production Line in Jiujiang Jiangxi

700TPH Stone Production Line in Jiujiang Jiangxi Stone Production Line in Yichun Jiangxi

Stone Production Line in Yichun Jiangxi 500TPH Stone Crushing Line for Sand Production

500TPH Stone Crushing Line for Sand Production 500TPH Aggregates Production Line in Guyuan Ningxia

500TPH Aggregates Production Line in Guyuan Ningxia 1500TPH Stone Production Line Installation Sites in Yibin

1500TPH Stone Production Line Installation Sites in Yibin 500TPH Stone Crusher Plant in Ziling Town Jingmen

500TPH Stone Crusher Plant in Ziling Town Jingmen 250-350TPH Hard Rock Crusher Plant in Xichang Sichuan

250-350TPH Hard Rock Crusher Plant in Xichang Sichuan 300TPH Stone Production Line in Nanchang Jiangxi

300TPH Stone Production Line in Nanchang Jiangxi 800TPH Limestone Production Line in Liuzhou Guangxi

800TPH Limestone Production Line in Liuzhou Guangxi Stone Crushing Plant in Daye Hubei

Stone Crushing Plant in Daye Hubei 600TPH Stone Crusher Plant in Nanchang Jiangxi

600TPH Stone Crusher Plant in Nanchang Jiangxi 420-500TPH Stone Production Line in Yushui Xinyu

420-500TPH Stone Production Line in Yushui Xinyu 300TPH Stone Production Line in Handan Hebei

300TPH Stone Production Line in Handan Hebei 5000 Ton/Day Fine Gravel Production Line for Sale

5000 Ton/Day Fine Gravel Production Line for Sale 3000TPH Stone Production Line in Hebei Province

3000TPH Stone Production Line in Hebei Province 300TPH Gravel Production Line of Mengding Yunnan

300TPH Gravel Production Line of Mengding Yunnan 1500TPH Stone Production Line in Guangxi

1500TPH Stone Production Line in Guangxi 300TPH Aggregate Production Line in Nanyang

300TPH Aggregate Production Line in Nanyang 160-210TPH Gravel Aggregates Production Line in Yichun

160-210TPH Gravel Aggregates Production Line in Yichun 800TPH Stone Production Line Shanxi

800TPH Stone Production Line Shanxi 800-1000TPH Stone Production Line in Pingxiang Jinagxi

800-1000TPH Stone Production Line in Pingxiang Jinagxi 1000TPH Stone Plant in Hohhot Inner Mongolia

1000TPH Stone Plant in Hohhot Inner Mongolia 3000TPH Gravel Aggregate Production Line of Dingli

3000TPH Gravel Aggregate Production Line of Dingli 200TPH Stone Plant in Laibin Guangxi

200TPH Stone Plant in Laibin Guangxi 160-210TPH Stone Production Line in Wanzai County

160-210TPH Stone Production Line in Wanzai County 1200TPH Stone Production Line of Zhongyuan Building Material

1200TPH Stone Production Line of Zhongyuan Building Material 250-320TPH Stone Production Line in Lianhua County

250-320TPH Stone Production Line in Lianhua County Production Line of 1500tph of Building Materials

Production Line of 1500tph of Building Materials Production Line of 1500tph of Aggregate

Production Line of 1500tph of Aggregate Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue 1100T/H Aggregate production line

1100T/H Aggregate production line 1000 TPH Mechanical Sand Production Line

1000 TPH Mechanical Sand Production Line 1000t/h limestone crushing processing system

1000t/h limestone crushing processing system 1000T/H Limestone Aggregate Production Line

1000T/H Limestone Aggregate Production Line Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 800t/h Stone Production Line

800t/h Stone Production Line 800-1500t/h Stone Production Line

800-1500t/h Stone Production Line 3000t/h Stone Production Line

3000t/h Stone Production Line 1000T/H Construction Aggregate Production Line

1000T/H Construction Aggregate Production Line 3000t/h Sand Aggregate Production Line

3000t/h Sand Aggregate Production Line 3000t/h Pebble Sand Production Line

3000t/h Pebble Sand Production Line 2500 tons of limestone crushing production line

2500 tons of limestone crushing production line 3000TPH gravel production line

3000TPH gravel production line