Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service ProviderCounterattack crushing machine, also called counterattack crusher, is a new type of efficient crushing equipment that featured with many advantages.

Capacity: 15-350t/h

Feed Size: ≤500mm

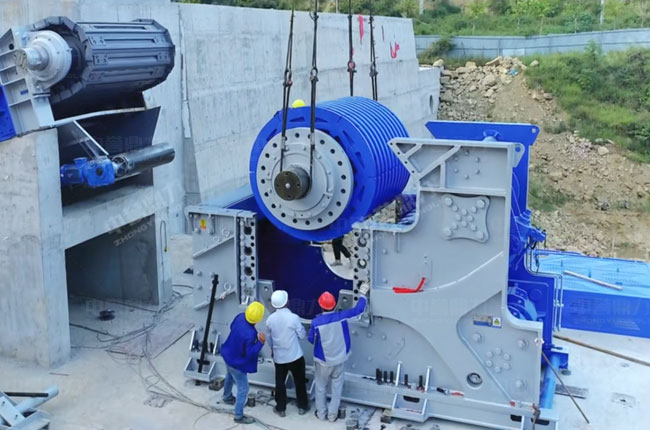

Counterattack crushing machine, also called counterattackcrusher, is new type of efficient crushing equipment that featured with the advantages of small size, simple structure, huge crushing ability, low energy consumption, high productivity, average product size, and selecting crushing. It can crush all ranges of coarse, medium, and fine materials like limestone, concrete, and granite with less than 500mm size and 350Mpa compressive strength.

Counterattack crusher can crush all kinds of coarse, medium, and fine materials of limestone, concrete, and granite with less than 500mm size and 350Mpa compressive strength in all the mineral, making artificial sand of railway, highway, and building industry.

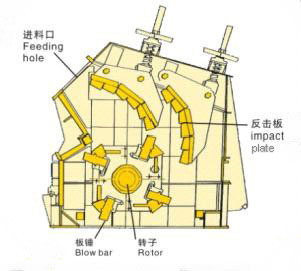

Counterattack crusher has the simple structure of shell, rotor, and impact plate. The main parts of impact crusher are with high speed rotor with plate hammer impacts materials in the process of back and forth. Impacted by hammer, plate, and materials, materials are crushed after crack and loose. The impact plate welded by steal and equipped with wear-resistant liner, impact bar, and grids is bearing hammer impacted material and then bouncing them back.

Counterattack crusher is a kind of crusher that crushed materials in using of impact strength. It works with high speed rotating that motivated by belt of energy motor. And as materials went into plate hammer area, it is crushed by hammer and then bounced back for the next crushing and then returned back into hammer area crushing again from impact liner, materials went into one, two, three impact chamber to get crushed and outlet of qualified size. You can control the material size and shape by adjusting the distance between impact table and rotor. By fell into the high speed rotating plate from the top of machine, aggregates crushed with the other aggregates in the high speed centrifugal force and then outlet from the bottom after getting impacted, rubbed, and smashed. This closed cycle that is controlled by screen equipment can reach the required size.

| Model | Specification(mm) | Feed Opening (mm) |

Maximum Feeding (mm) | Capacity(t/h) | Power(kw) | Machine Size(mm) |

| PF-1007 | 1000×700 | 400×730 | 250 | 15-60 | 37-55 | 2330×1660×2300 |

| PF-1010 | 1000×1050 | 400×1080 | 300 | 50-90 | 55-75 | 2370×1700×2390 |

| PF-1210 | 1250×1050 | 400×1080 | 300 | 60-120 | 95-110 | 2580×2080×2750 |

| PF-1214 | 1250×1400 | 400×1430 | 300 | 130-180 | 132-170 | 2690×2360×2750 |

| PF-1315 | 1325×1500 | 860×1520 | 350 | 160-250 | 180-260 | 2890×2680×3090 |

| PF-1320 | 1320×2000 | 860×2030 | 500 | 160-350 | 300-375 | 2870×3350×3090 |

Note: Specifications are subject to change without notice. Please refer to the real machine data.

Annual production line of 10 million tons of cobblestones

Annual production line of 10 million tons of cobblestones Crushing Production Line of 1000tph of Coal Gangue

Crushing Production Line of 1000tph of Coal Gangue Production line of 3,000 tons of limestone

Production line of 3,000 tons of limestone limestone crushing plant with a capacity 0f 3,000 tons an hour

limestone crushing plant with a capacity 0f 3,000 tons an hour Tower like Sand making

Tower like Sand making 2000t/h Sand production line

2000t/h Sand production line 1100T/H Aggregate production line

1100T/H Aggregate production line 3000t/h Stone Production Line

3000t/h Stone Production LineFree consultation on related issues.